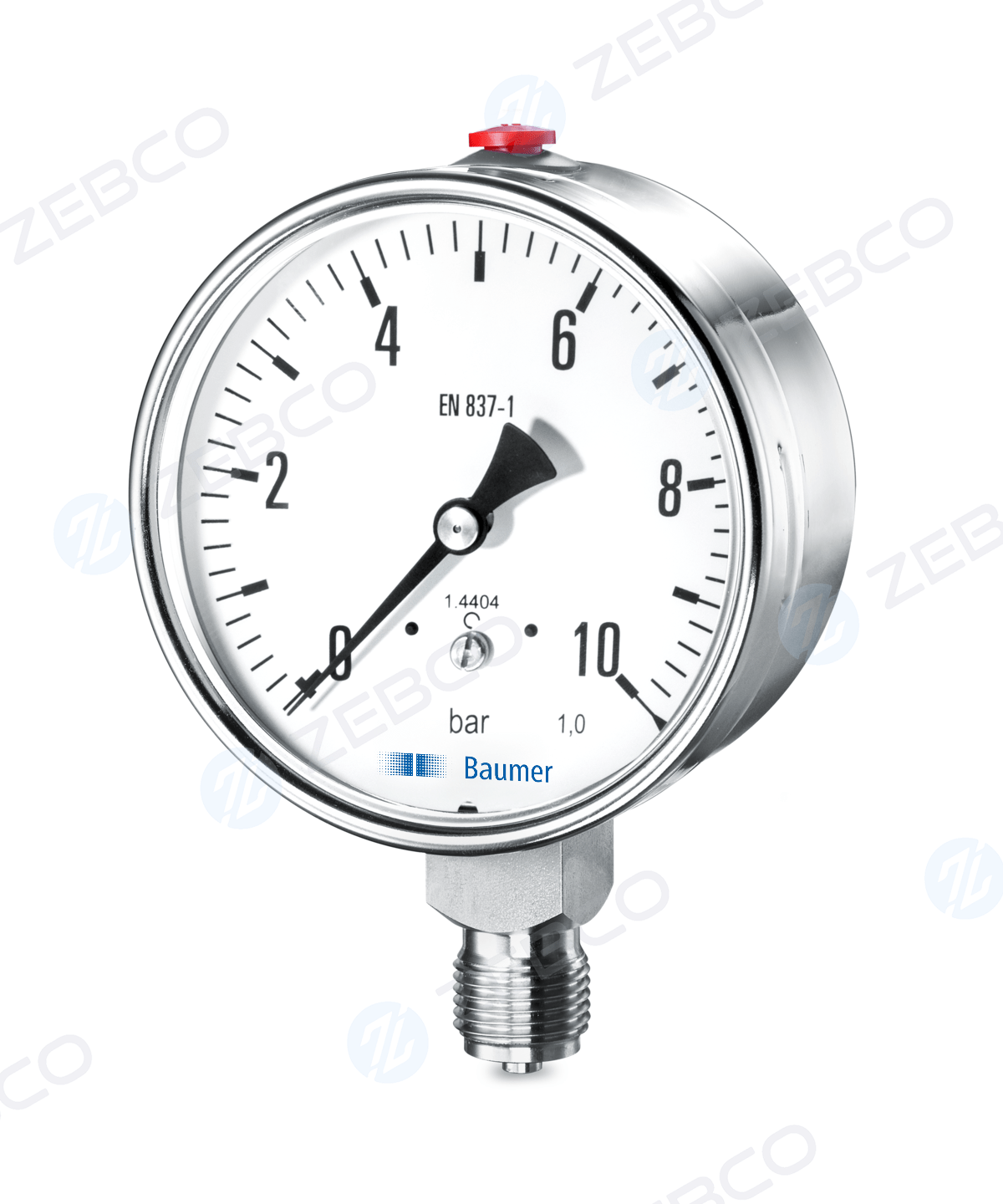

Baumer Stainless Steel Bourdon type Pressure Gauge (AL Model)

Reliable and durable Baumer All SS Pressure Gauge (AL Model), featuring Bourdon tube technology. Designed for precise pressure measurement in industrial applications involving corrosive media, high pressure and extreme temperatures. Compliant with EN 837-1 and ASME B40.100 standards. Available in dial sizes 100mm and 150mm.

- External zero adjustment (optional)

- Stainless steel case & measuring system

- Socket directly welded to case

- Dry and liquid filled version

- Standard followed EN 837-1 (for NS 100, 150 & 250 mm)

- CE marking (as per PED 97/23/EC) (for NS 100 mm & 150 mm)

Application of Bourdon type Pressure Gauge (AL Model)

- Food & beverage

- Hydro-cleaning machines

- Pharmaceutical

- Presses

- Cryogenics

- Engine compressors

- Pumps

- Diesel engines & Refrigerating plants

- Turbines

- Chemical & Petrochemical industries

- HVAC & Refrigerating plants

- Conventional & nuclear power plants

- Environments & gaseous or liquid media that will not obstruct the pressure system.

Extended Product Description for Baumer All SS Pressure Gauge (AL Model)

The Baumer All Stainless Steel Pressure Gauge (AL Model) is a robust, high-precision mechanical gauge designed for reliable pressure measurement in harsh and corrosive environments. Featuring Bourdon tube technology and a full 304/316 stainless steel construction, it offers excellent resistance to aggressive media and extreme process conditions.

This gauge is suitable for measuring the pressure of gases, vapors and liquids, and is commonly used in chemical plants, petrochemical facilities, food processing, marine applications, power plants and HVAC systems. Its compact and durable design, combined with high accuracy (±1.0% or ±1.6% F.S.), makes it ideal for both general-purpose and demanding industrial applications.

Available in dial sizes of 100mm and 150mm, the AL Model supports various mounting options (bottom or back entry, surface or panel mounting) for flexible installation. It complies with EN 837-1 and ASME B40.100 standards, ensuring international quality and performance.

Whether you're working with corrosive chemicals, high-pressure systems or applications requiring sanitary and long-lasting instruments, the Baumer AL Model delivers dependable performance and longevity.

Specifications

Standard Dial Size : 100 mm, 125 mm, 150 mm, 200 mm, 250 mm

| Accuracy Class | : | ±1.0% of Full Scale (as per EN 837-1 or ASME B40.100) |

| Ambient temperature | : | - 25°C to + 65° C |

| Process temperature | : | Maximum process temperature: 300° C |

| Operating pressure | : | Steady Pressure: up to 75% of Full Scale |

| : | Fluctuating Pressure: up to 66% of Full Scale | |

| : | Short-Term Pressure: up to 100% of Full Scale | |

| Overpressure limit | : | For pressure ranges <100 bar: up to 125% of full scale |

| : | For 100 to 600 bar: up to 115% of full scale | |

| : | For 600 to 1600 bar: up to 110% of full scale |

| Case & Bezel | : | AISI 304 SS (Bayonet Type) |

| Bourdon | : | AISI 316L SS |

| Socket | : | AISI 316L SS (Directly Welded to Case) |

| Movement | : | AISI 304 SS |

| Joints | : | Tig Argon Arc Welding |

| Protection | : | IP 65 |

| Dial | : | Aluminium, black graduation on white background |

| Pointer | : | Aluminium, black coloured Micrometer zero adjustable |

| Window | : | Sheet Glass |

| Blow off Disc | : | Neoprene |

| Gasket & Filling Plug | : | Neoprene |

Baumer vs WIKA Pressure Gauges – Brand Comparison Guide

Compare Baumer and WIKA pressure gauges across key factors like construction, accuracy, safety features, industry suitability and cost. This side-by-side guide helps you choose the right brand for your application—whether you need hygienic precision or rugged industrial performance.

| Feature / Specification | Baumer | WIKA |

|---|---|---|

| Country of Origin | ||

| Construction | Full SS 304/316 (Case & Wetted parts) | Full SS 316L, with solid-front safety versions |

| Design Focus | Compact, Hygienic, Corrosion-resistant | Heavy-duty, Rugged, Safety-oriented |

| Accuracy | ±1.0% or ±1.6% FS | ±1.0% or ±0.5% FS (in premium models) |

| Dial Sizes Available | 63 MM, 100 MM, 150 MM, 250 MM | 63 MM, 100 MM, 160 MM, 250 MM |

| Pressure Ranges | 0…0.6 bar to 0…1600 bar | 0…0.6 bar to 0…1600 bar |

| Overpressure Protection | Up to 125% of full scale (varies by range) | Up to 130% (short-term), 90% (fluctuating), 100% (steady) |

| Temperature Range (Ambient) | -20°C to +65°C | -40°C to +60°C (varies with fill) |

| Process Temp Limit | Up to 300°C (with capillary/remote seal) | Up to 200°C (with appropriate filling) |

| Fill Options | Glycerin, Silicone, Dry | Glycerin, Silicone, Dry |

| Vibration Resistance | Good – with optional filling | Excellent – especially with fill & solid-front design |

| Safety Features | CE, ATEX, EAC, NACE approvals | Solid front, blow-out back, pressure relief disk |

| Certifications | EN 837-1, ASME B40.100, ATEX, CE, EAC | EN 837-1, ASME B40.100, ATEX, CE, EAC, ISO |

| Ideal Industries | Food & Beverage, Pharma, Automation, Water Treatment | Petrochemicals, Oil & Gas, Power Plants, Heavy Machinery |

| Customization Options | Dial, Mount, Connection, Fill Fluid | Full customization: Dials, Connections, Wetted parts, Branding |

| Distribution in India | Authorized dealers like Zebco Engineering LLP | Widely Available; Global & Local distributors |

| Relative Cost | Competitive / Mid-range | Higher-end / Premium-priced |

| Reliability Feedback | High for Clean/Process environments | Very high in Industrial/Heavy-duty settings |

Why India’s Top Industries Choose Zebco for Baumer Pressure Gauges?

Zebco Engineering LLP is an authorized and experienced distributor of Baumer pressure gauges in India, offering technical expertise, genuine products and tailored service. Here's why professionals trust Zebco for Baumer solutions:

Authorized Supplier

Direct access to 100% genuine Baumer instruments with manufacturer-backed support and warranty.

Competitive Pricing

Over 20 years of experience in supplying pressure solutions for pharma, chemical, food and industrial sectors.

Reliable Delivery

Wide inventory of Baumer gauges with options for dial sizes, mounting, connections and fast delivery.

After-Sales Support

Expert guidance on model selection, application fit and after-sales service from qualified engineers.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engi neering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!