Baumer pressure gauges are widely used across Indian industries for reliable and accurate pressure measurement. This guide explains each Baumer model in detail and helps engineers, buyers and plant managers select the right gauge. At the end you’ll find why Baumer is a smart choice and exactly how Zebco helps - from model selection and datasheets to best-price delivery from ready stock.

About Baumer – Swiss Precision in Industrial Pressure Measurement

Baumer Group is a globally respected Swiss manufacturer specializing in industrial sensors and measuring instruments, known for combining engineering precision, rugged construction, and long-term reliability.

With over 70 years of experience, Baumer has built a strong reputation in pressure, temperature, level, and process instrumentation for demanding industrial environments across Europe, Asia, and emerging markets like India.

Baumer pressure gauges are designed to perform reliably under high vibration, temperature fluctuations, corrosive media, and continuous duty cycles, making them especially suitable for Indian industrial conditions.

Baumer Pressure Gauge Models – Detailed Explanation

AL Series

All stainless steel process gauges for high pressure industrial services.

AD Series

Compact anti-vibration gauges for OEM and machinery applications.

AF Series

Weatherproof gauges for outdoor and field duty.

AP Series

Panel mounted gauges for control panels and skids.

AI Series

Explosion proof gauges for hazardous areas.

AZ Series

Hygienic gauges for pharma, dairy and food industries.

DB Series

Diaphragm seal gauges for corrosive and viscous media.

DG Series

Differential pressure gauges for filters and HVAC.

DH Series

Heavy duty gauges for high pressure systems.

DJ Series

Low pressure and capsule gauges.

DK Series

Digital pressure gauges and transmitters.

DO Series

Flush diaphragm gauges for hygienic processes.

Why Baumer Pressure Gauge Is Better Than Local / Unbranded Gauges

Baumer is a global leader in industrial sensors, pressure gauges, transmitters, and automation solutions, known for their precision and reliability. With a strong presence in India and worldwide, Baumer’s products enhance efficiency and safety across industries like manufacturing, robotics, and process control. Here are some compelling points that explain why Baumer pressure gauges are a better choice:

1. Swiss Engineering and Design

- Precision and Quality: Baumer is renowned for its Swiss craftsmanship and engineering excellence. Swiss-made products are globally recognized for their precision, durability, and attention to detail.

- Innovative Design: Baumer integrates innovative design concepts into their products, ensuring that the gauges are not only reliable but also feature advanced technology and user-friendly interfaces.

2. High-Quality Materials and Manufacturing

- Superior Materials: Baumer uses high-grade materials such as stainless steel, which ensures better resistance to corrosion, high temperatures, and pressure conditions compared to many local or unbranded gauges.

- Consistency and Durability: Their products undergo strict quality control during the manufacturing process, ensuring long-term reliability and accuracy even in challenging environments.

3. Precise Calibration

- Factory Calibration: Baumer pressure gauges are calibrated in precision laboratories, ensuring that they deliver highly accurate measurements right from the start. This precise calibration ensures consistency and reliability in performance.

- Traceable to International Standards: Baumer offers traceable calibration certificates that confirm the gauges' accuracy, often based on international standards such as ISO 9001 or national metrology standards.

4. Certification and Approvals

- Certified Compliance: Baumer gauges come with certificates that prove they comply with key international standards (e.g., CE, ISO 9001, ATEX for hazardous environments), which is a strong assurance of product reliability.

- Industry-Specific Certifications: For applications in industries such as food & beverage, pharmaceuticals, oil & gas, or aerospace, Baumer products have the necessary industry-specific approvals that local gauges may lack.

5. Warranty and After-Sales Support

- Comprehensive Warranty: Baumer typically offers warranties that ensure long-term protection and support for their products. Their after-sales service is known for being responsive and helpful, offering peace of mind for the end user.

- Global Service Network: Unlike local or unbranded gauges that may lack adequate support, Baumer has a global network of service centers and trained technicians ready to assist with maintenance and repairs.

6. Accuracy and Long-Term Reliability

- Higher Accuracy: Baumer pressure gauges are engineered for higher accuracy and repeatability, reducing the risk of operational errors or faulty readings that could have serious consequences.

- Consistency Over Time: Due to superior materials and manufacturing, Baumer gauges maintain their accuracy and reliability for longer periods, reducing the frequency of replacements and recalibration.

7. Ease of Use and Versatility

- Clear Display and User Interface: Baumer gauges often come with clearly readable dials, digital displays, or color-coded zones for ease of use, making them more user-friendly than many local or unbranded alternatives.

- Customization Options: Baumer offers various models, including digital, analog, and remote types, to cater to diverse industry requirements, something that local gauges might not be able to match in terms of variety or customization.

8. Global Reputation and Brand Trust

- Well-Established Brand: Baumer has built a reputation for producing reliable and high-performance instruments worldwide. Their brand is synonymous with quality, which provides additional confidence for users looking for a trusted product.

- Industry Recognition: Baumer is recognized across various sectors for its precision and long-standing contribution to industrial measurement, further reinforcing its credibility compared to unbranded alternatives.

9. Environmental and Safety Standards

- Safety Features: Baumer pressure gauges are often designed with safety in mind, including features like overpressure protection, anti-vibration mechanisms, and flameproof casings for hazardous environments.

- Environmental Considerations: Many Baumer gauges are built to comply with environmental standards, reducing the risk of hazardous emissions or material degradation that could compromise operational safety.

10. Longer Lifecycle and Cost-Effectiveness

- Cost-Effectiveness Over Time: While Baumer pressure gauges might have a higher upfront cost compared to local, unbranded gauges, their longer lifespan and reduced risk of malfunction or inaccuracy often make them more cost-effective in the long run.

- Reduced Maintenance Costs: Because of their durability and precision, Baumer gauges require less frequent maintenance, leading to lower operational and repair costs.

Why Baumer Pressure Gauges Stand Out in the Global Market

1. Swiss Engineering with Industrial Practicality

Baumer instruments are developed in Switzerland with a strong focus on:

- Mechanical accuracy

- Long service life

- Minimal maintenance

- Consistent performance under harsh conditions

Unlike low-cost gauges that drift quickly, Baumer gauges maintain calibration stability over extended operating periods.

2. All-Stainless-Steel Construction as Standard

Most Baumer pressure gauge models feature:

- SS304 / SS316 case

- SS316L wetted parts

- Robust bourdon tube and diaphragm assemblies

This makes Baumer gauges ideal for:

- Chemical plants

- Oil & gas installations

- Power plants

- Water treatment facilities

- OEM machinery

3. Wide Model Range for Every Industry Need

Baumer offers one of the most comprehensive pressure gauge portfolios, including:

- AL & AD Series – All SS gauges for general industrial use

- AF / AP / AI / AZ Series – Compact and panel-mounted OEM gauges

- DG / DH / DJ / DK / DO Series – Process and safety pattern gauges

- Diaphragm Seal Gauges – For corrosive, viscous, or hygienic applications

Model-by-model details

Baumer product families often have multiple sub-variants and customizable options (wetted material, connection, diaphragm seal, fill fluid). Below we describe typical/commonly-specified configurations and the problems they address.

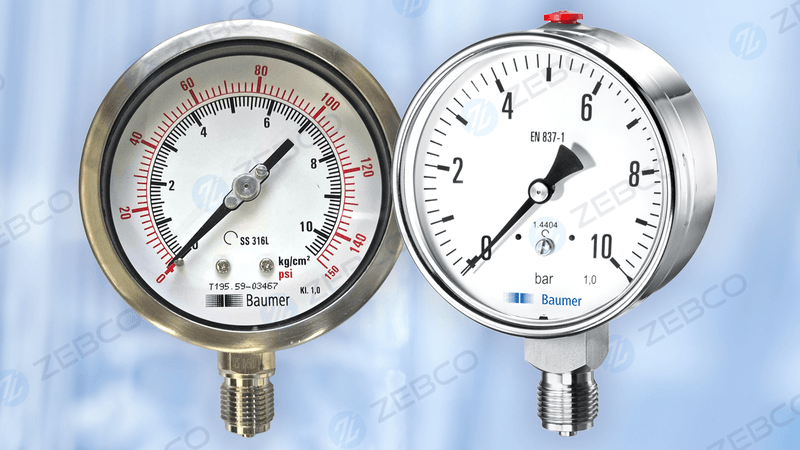

1. AL Series - All-Stainless Steel Process Gauges (4″/6″/8″/10″ dials)

Full-size process gauges in stainless steel (case + wetted parts), available in larger dial sizes for remote visibility. Safety-pattern options available (solid front / blow-out back).

Typical construction & features

- SS304 / SS316 case and wetted parts (Bourdon tube SS316)

- Large dial sizes (100 mm, 150 mm and higher) for easy reading at distance

- Safety-pattern variants (Solid front, Blow-out back)

- Options: Glycerine/silicone filling, capillary, syphon, diaphragm seal interface

Use cases

- Control rooms and process lines where readability is critical

- High-pressure utility and process lines (pump discharge, steam, compressors)

- Panels in plant yards and high-visibility locations

Problems solved / benefits

- Readable indication at distance for operators (reduces operator error)

- Robustness in harsh environments (SS construction resists corrosion)

- Safety-pattern variants protect personnel during overpressure events

Industries

Oil & Gas, Petrochemical, Power, Water Treatment, Cement, Heavy Manufacturing, Refineries, Semiconductor

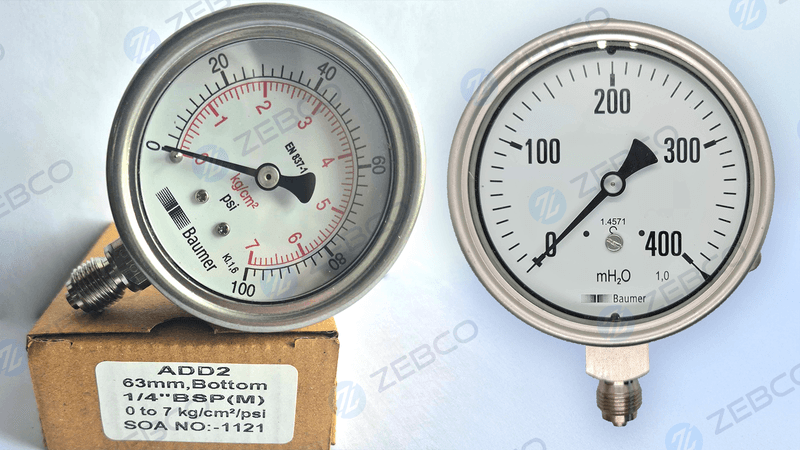

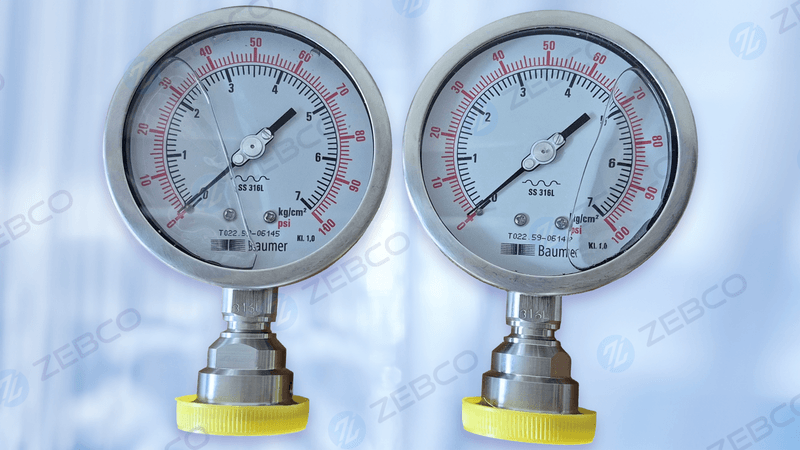

2. AD Series - Compact / Panel / Anti-Vibration Gauges (2″ & 2.5″ dials)

Small, rugged pressure gauges optimized for panel mounting and OEM equipment - ideal where space is limited and vibration is present. Typical construction & features

- 2” / 2.5” dial sizes, SS or stainless-front options

- Liquid-filled (glycerine or silicone) options standard for vibration damping

- Back or bottom entry options for neat panel installation

Use cases

- OEM machines, compressors, hydraulic power packs, control panels, skid-mounted equipment

Problems solved / benefits

- Compact footprint for tight panels

- Liquid fill avoids pointer jitter and premature wear in vibrating machinery

- Quick fit for mass production / OEM supply

Industries

OEMs, Machine Builders, Packaging, Compressors, Instrument Panels across industries

3. AF Series — Field / Weather-Proof Gauges (All-SS Capsule type)

Field-duty, weather-resistant all SS pressure gauges often with enhanced sealing and optional sun-shield/hood.

Typical construction & features

- IP65 / IP66 design options (high ingress protection)

- Sealed case, optional heater or anti-fog insert

- Large dial options available for outdoor readability

Use cases

- Outdoor pump stations, remote instrumentation booths, marine / coastal installations

Problems solved / benefits

- Resistant to rain, dust and coastal corrosion

- Reduced fogging and condensation in humid conditions

- Sturdier case reduces maintenance visits

Industries

Water Treatment, Marine, Irrigation, Offshore Utility Stations, Infrastructure

4. AP Series — Panel & Flange Mount Gauges (Flush Mounting)

Steel Case Low & High Pressure Gauge Diaphragm type optimized for panel and flange mounting - front-flange design for secure panel integration and flush mounting.

Typical construction & features

- Front-flange mounting for panels, control desks

- Optional panel-ring sealing and gasketed flange

- Dial customisation (logo, scaled markings)

Use cases

- Operator control cabinets, centralized monitoring panels, OEM dashboards

Problems solved / benefits

- Clean panel integration, tamper-resistant mounting

- Custom dials for process technicians (scaled ranges, colour zones)

- Easier service/replace without removing entire panel

Industries

Process control rooms, OEM control panels, Skid manufacturers

5. AI Series - Intrinsically Safe / Ex-proof Variants (for hazardous area)

All SS Pressure Gauge with Solid Front Intrinsically safe or explosion-protected variants suitable for Zone 0/1/2 (gas) or Zone 20/21/22 (dust) areas when specified.

Typical construction & features

-

Flameproof housings or intrinsically safe certification options (ATEX/IECEx on request)

-

Non-sparking internal construction, sealed cases

-

Often combined with safety-pattern case designs Use cases

-

Fuel storage, gas compression, solvent handling, hazardous chemical processes

Problems solved / benefits

- Safe use in explosive atmospheres for operator protection and regulatory compliance

- Avoids ground-up project redesign to meet hazardous area requirements

Industries

Oil & Gas (hazardous zones), Petrochemical, Solvent processing, Paint & coatings plants

6. AZ Series — Hygienic / Tri-clamp / Sanitary Gauges (flush diaphragm & triclover)

Homogenizer Pressure Gauge Diaphragm Hygienic gauges with flush diaphragm and Tri-Clamp (Tri-Clover) connections for CIP/SIP applications.

Typical construction & features

- Flush diaphragm (no dead space), Tri-Clamp / Tri-Clover connections

- SS316L wetted parts, electropolished surfaces on request

- Designed for CIP/SIP sterilization cycles and easy cleaning

Use cases

- Food & beverage lines, dairy, brewery, pharmaceutical reactors, sterile product lines

Problems solved / benefits

- Prevents microbial harbouring: hygienic design ensures cleanliness

- Easy removal & cleaning during shutdowns

- Maintains sanitary process integrity (minimizes contamination risk)

Industries

Pharma, Biotech, Food & Beverage, Dairy, Beverage

7. DB Series — Diaphragm Seal Integrated Gauges (direct-seal family)

Diaphragm Seal Direct coupled type Pressure Gauges supplied as integral diaphragm-seal assemblies for corrosive / viscous / hot media that must not contact the gauge internals.

Typical construction & features

- Seal materials: PTFE-lined, Tantalum, Hastelloy, Monel, SS316L per media compatibility

- Available in flange, threaded and sanitary connections

- Fill fluids: silicone, glycerine, specialised filling fluids for temperature stability

Use cases

- Acid dosing lines, effluent treatment, slurry feed, catalytic reactors Problems solved / benefits

- Direct isolation — prevents clogging and corrosion of gauge internals

- Enables accurate reading with aggressive media by remote-fill capillary if needed

- Extends instrument life and reduces maintenance frequency

Industries

Chemical, Fertilizer, Paper & Pulp, Mining, Semiconductor, Effluent Treatment

8. DG Series — Differential Pressure Gauges (DP / filter monitoring)

Dedicated differential pressure gauges to measure pressure drop across filters, strainers, or across two points in process equipment.

Typical construction & features

- Two process connections (high & low) with differential movement gear

- Can be direct-reading (ΔP) or with dual pointers

- Option for setpoint alarm flags and electrical contacts

Use cases

- Filter element monitoring (air & liquid), boiler/steam traps, HVAC filters, compressor.

Problems solved / benefits

- Simple, visual indication of filter clogging & maintenance trigger

- Prevents downstream damage by early detection of pressure differential issues

Industries

Water Treatment, HVAC, Pharma (cleanroom filters), Food & Beverage, Industrial Filtration

9. DH Series — Heavy-Duty / High-Pressure Gauges

Diaphragm Sanitary Seal Gauges designed for very high pressure, robust construction and high overload capacity.

Typical construction & features

- Reinforced Bourdon tubes, heavy cases, larger thread sizes

- High-range calibration up to model capability (specify per project)

- Often fitted with safety-pattern design and blow-out protection

Use cases

- High-pressure hydraulic systems, compressor discharge lines, test benches

Problems solved / benefits

- Withstand high overpressure events and cyclic loading

- Provide reliable readings in heavy-duty process lines

Industries

Hydraulics, Heavy Manufacturing, Oil & Gas, Test Houses, high-pressure process units

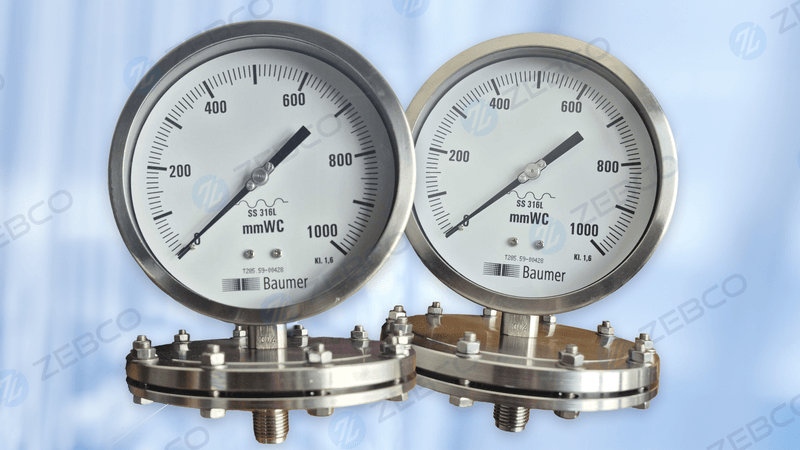

10. DJ Series — Low-Pressure / Capsule Gauges (vacuum & mbar ranges)

Diaphragm Seal Direct flanged flushed Capsule / bellows type gauges for low-pressure, vacuum and differential near-zero readings.

Typical construction & features

- Capsule element or bellows, highly sensitive movement for mbar-level detection

- Dial scales in mbar, mmWC, inH₂O for HVAC and burner control

Use cases

- Clean-room differential, burner/combustion air, ventilation, gas train low pressure

Problems solved / benefits

- Accurate detection of small pressure differences critical for burner safety and air-handling

Industries

HVAC, Boiler control, Combustion systems, Laboratory, Gas distribution panels

11. DK Series — Digital Pressure Gauges / Transmitters (hybrid family)

Diaphragm Seal Direct flanged insert type Digital indicators or electronic pressure transmitters in Baumer family for higher accuracy, data logging, and electronic outputs.

Typical construction & features

- LCD or LED display, configurable units, alarm outputs

- Electrical outputs: 4–20 mA, HART, or digital bus (depending on variant)

- Battery or loop-powered options

Use cases

- Calibration, remote monitoring, integration with DCS/PLC, data logging during commissioning

Problems solved / benefits

- Higher accuracy / traceability for critical processes

- Integration into plant automation and predictive maintenance

Industries

All industries with automation needs: Pharma, Process, Power, Oil & Gas, Water

12. DO Series — Flush-Diaphragm & Sanitary Direct-Mount Gauges (specialty)

Diaphragm Seal Slip ring coupled type Flush-diaphragm gauges for sanitary and very viscous media where flush mounting is required.

Typical construction & features

- Flush diaphragm (no dead zone) for high-purity lines

- Tri-clamp or hygienic flange connections

- Compatible with CIP/SIP cleaning cycles

Use cases

- Viscous product lines, food syrups, dairy and pharma sterile liquids

Problems solved / benefits

- Eliminates product build-up and dead space

- Maintains process hygiene and reduces cleaning cycles

Industries

Food, Dairy, Pharma, Cosmetic, Beverage

How to read this and pick the right model (quick decision map)

- Is the medium corrosive or slurry? → DB / Diaphragm Seal / PTFE or exotic alloy diaphragms.

- Is the process hygienic / CIP critical? → AZ / DO (Tri-clamp / flush diaphragm).

- High vibration/pulsation? → AD (liquid-filled, anti-vibration).

- Large dial needed (remote reading)? → AL series.

- Low pressure / vacuum? → DJ Capsule / Bellows.

- Need electronic output / logging? → DK digital/transmitter.

- Hazardous area? → AI / certified explosion-proof variant.

- Need differential monitoring? → DG differential gauge.

- High-pressure heavy duty? → DH heavy-duty series.

- Outdoor / field conditions? → AF field/weather-proof variant.

Why Baumer Pressure Gauges are the Right Choice for Your Industry (short, practical reasons)

- Balanced performance & price: European engineering quality without the absolute premium of some German competitors — excellent value for Indian projects.

- Material selection & options: Wide choice of diaphragms and exotic alloys (Tantalum, Hastelloy, Monel) for corrosive service.

- Robust options for vibration & pulsation: AD series and liquid filling protect reading stability and instrument life.

- Complete hygienic options: Flush diaphragms and Tri-Clamp variants for pharma & food.

- Easy customization: Dial markings, custom ranges, capillaries, remote mount options to match project specs.

How Zebco helps you choose & get the best (we are not just sellers)

Zebco Engineering LLP is positioned as a technical partner — not just an order-taker. Here are the ways we help your project succeed:

1. Expert selection & application engineering

- We review your process datasheet (media, temp, pressure, connection, PID points) and recommend the exact pressure gauge model & variant.

- Provide compatibility chart (media vs. diaphragm material) and explain trade-offs (cost vs. longevity).

2. Exact specification & datasheet pack

- We deliver complete model code, datasheet, dimensional drawing, calibration certificate and recommended spares for the project package.

3. Ready stock & fastest delivery (price advantage)

- Zebco holds ready stock of common Baumer AL/AD/ALF types and diaphragm seal assemblies in India — that reduces lead time and procurement cost.

- Bulk project pricing and OEM rates reduce unit cost — we pass on manufacturer discounts.

- Our logistics partners ensure on-time delivery and drop-ship options.

4. Price transparency & best deal guarantee

- We give clear, competitive quotes with no hidden charges. For project orders, we share cost breakup (instrument + seal/customisation + calibration + packaging).

- Authorized dealer status means genuine product and warranty support.

5. Practical commissioning & after-sales support

- Installation guidelines (syphon for steam, capillary routing, orientation, torque settings) provided.

- Calibration / re-certification options; spare parts / replacement policy.

- Troubleshooting assistance: we diagnose field problems (vibration, clogging, wrong range) and provide corrective actions.

6. Project & tender support

- We prepare technical submittals, offer letters, compliance documents, and support for vendor approvals (PQQ, bid submission).

Pricing, stock & procurement — practical notes

- Common items (AL/AD standard ranges, Glycerin-filled versions, AD compact gauges): typically in-stock or short lead-time in India.

- Special items (Tantalum diaphragms, Hastelloy, ATEX-certified versions): need confirmation; we typically stock some options or can procure quickly from Baumer.

- Best way to get price: Share process datasheet (media, temp, pressure range, connection, qty) → Zebco issues competitive quote and lead time.

- Payment & delivery: Project-friendly payment terms for OEMs and regular customers; expedited shipping options available.

Example customer scenarios (how Zebco solves real problems)

Scenario 1: Chemical plant facing frequent gauge corrosion on acid dosing lines.

Solution: Replace brass gauges with DB series (PTFE-lined diaphragms) + remote capillary for temperature isolation + provide spare diaphragms and maintenance checklist.

Scenario 2: Compressor skid suffering pointer jitter and short life.

Solution: Replace with AD series liquid-filled anti-vibration gauge, add snubber and shock dampers, provide installation orientation guidance - life increases dramatically.

Scenario 3: Pharma firm needs hygienic flush gauges for WFI lines.

Solution: Supply AZ / DO tri-clamp gauges with SS316L, electropolishing option, CIP/SIP validation certificates, and FAT / calibration report.

How to use this guide

- Identify your process (media, temp, pressure range, environment).

- Read the model(s) that match your requirements.

- Check the “why it helps” and “industries” lines for fit.

- Ask Zebco for a datasheet + exact model code, lead time and price.

Technical appendix (Quick Reference)

- Common materials: SS304, SS316, SS316L, Hastelloy, Monel, Tantalum, PTFE lining

- Typical fill fluids: Glycerine (0-60°C), Silicone (-40°C to 200°C)

- Standards: EN 837-1 (mechanical Gauges), ASME B40.1 equivalents for dial gauges; ATEX / IECEx for hazardous area variants (when requested)

- Accuracy classes: 0.5%, 0.6%, 1.0%, 1.6% typical (specify with model code)

What you should do next

- Send us 1 page process datasheet (media, temperature, pressure range, connection type, quantity).

- We will return a recommended model list (Baumer exact model codes), datasheets, lead times and best price within 24 hours.

- If you want, we will deliver a sample and provide onsite commissioning support.

Contact: sales@zebcoeng.com | +91 98982 26321 | www.zebcoeng.com www.zebcoeng.in