Gate valves are essential components in industries where flow control and isolation of liquids, gases, or steam are crucial. Without reliable flow control systems, industries face inefficiencies, safety risks, and costly downtimes. As a leading supplier and manufacturer, Zebco Engineering LLP offers a comprehensive range of gate valves designed to meet diverse industrial needs. This blog explores the types of gate valves, their materials, design standards, industrial applications, benefits, and why Zebco Engineering LLP is the preferred choice.

Introduction

Gate valves play a pivotal role in industrial systems, ensuring efficient operation and safety. They are indispensable in managing the flow of various media, including water, oil, gas, and chemicals. This guide provides an overview of gate valves and how Zebco Engineering LLP’s expertise delivers unmatched solutions for industrial challenges.

Types of Gate Valves

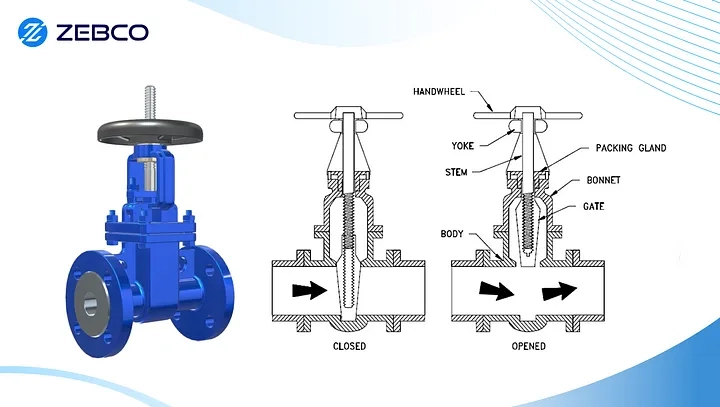

Gate valves are classified based on their design and functionality. Each type serves specific applications:

- Rising Stem Gate Valve: Provides a visual indicator of the valve’s position as the stem rises when the valve is open. Commonly used in water and wastewater systems.

- Non-Rising Stem Gate Valve: Suitable for confined spaces and underground installations, as the stem does not extend externally.

- Wedge Gate Valve: Features a wedge-shaped disc that ensures a tight seal, ideal for high-pressure systems.

- Parallel Slide Gate Valve: Designed for high-temperature and high-pressure applications using parallel discs to isolate flow.

- Knife Gate Valve: Handles viscous fluids, slurries, and solids, making it a preferred choice in mining and pulp industries.

Materials of Construction

The material of a gate valve determines its durability, resistance to environmental conditions, and suitability for specific media. Zebco Engineering LLP offers gate valves made from:

- Cast Iron: Economical, suited for low-pressure applications. Ca- rbon Steel: Durable and strong, suitable for high-pressure systems.

- Stainless Steel: Corrosion-resistant, ideal for chemical and marine environments.

- Duplex Steel: Combines strength and corrosion resistance, perfect for aggressive environments.

- Bronze: Highly durable and corrosion-resistant, ideal for water applications.

- Alloy Steel: Withstands high temperatures, used in power and petrochemical industries.

Providing a comparison table of materials and their ideal applications would make this section more comprehensive.

Design and Manufacturing Standards

Zebco’s gate valves adhere to stringent international standards, ensuring reliability and safety:

- API 600: Specifies steel gate valves for pipeline applications.

- ASME B16.34: Covers valves with flanged, threaded, and welding ends.

- BS 5150: Defines cast iron wedge and double-disc gate valves

- ISO 9001: Ensures compliance with quality management systems.

Highlighting Zebco’s robust quality assurance process ensures trust in the reliability of the products.

Industries Using Gate Valves

Gate valves serve a wide range of industries due to their versatility and durability:

- Oil and Gas: Used for pipeline isolation and process flow control.

- Petrochemical: Handles aggressive chemicals and high-pressure systems.

- Water Treatment: Regulates water flow in municipal and industrial setups.

- Power Generation: Manages steam flow and isolation in thermal plants.

- Mining: Handles abrasive slurries and fluids with solid particles.

Including case studies or examples of successful applications can make this section more relatable and impactful.

Benefits of Gate Valves

- Effective Shutoff: Provides a reliable and tight seal to prevent leakage.

- Minimal Flow Resistance: A fully open valve ensures an unobstructed flow path.

- Versatility: Suitable for various media and operational conditions.

- Durability: Withstands high pressures and temperatures with ease.

- Cost-Effective: Low maintenance requirements and long service life reduce operational expenses.

Why Choose Zebco Engineering LLP?

Zebco Engineering LLP distinguishes itself as a trusted name in gate valve manufacturing and supply. Here’s why:

- Extensive Range: Offers a comprehensive selection of gate valves tailored to specific industrial needs.

- Quality Assurance: Every valve undergoes rigorous testing to meet international standards.

- Technical Expertise: Decades of engineering experience ensure cutting-edge valve solutions.

- Global Reach: Supplies high-quality valves to industries worldwide, meeting diverse requirements.

- Customer-Centric Approach: Delivers customised solutions, prompt service and competitive pricing.

Conclusion

Gate valves are critical for efficient and safe operations across various industries. Zebco Engineering LLP’s dedication to quality, innovation, and customer satisfaction positions it as a leader in industrial gate valve solutions. To learn more, visit our website or contact our team today.