The Importance of Choosing the Right Pressure Gauge

In the world of industrial operations, precision matters. Pressure gauges are fundamental tools that help industries monitor and control the pressure of gases and liquids. Whether in a pharmaceutical plant or a chemical processing unit, the ability to monitor pressure accurately ensures safety, efficiency, and regulatory compliance.

Among the top contenders in the pressure instrumentation space are Baumer and WIKA, two globally recognized brands known for their high-quality pressure gauges. This blog offers a side-by-side comparison of these industry leaders to help you make an informed choice.

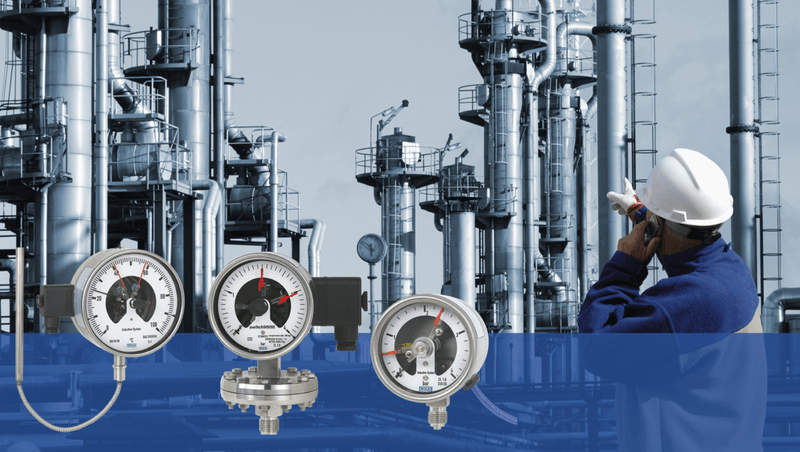

Why Pressure Gauges Matter in Industrial Applications

Pressure gauges are critical in a variety of industries:

- Oil & Gas

- Pharmaceuticals

- Chemical Processing

- Water & Wastewater Treatment

These instruments help prevent accidents, detect system failures, and maintain compliance with standards such as ISO, CE, and ATEX. They’re also vital for preventive maintenance, helping avoid costly downtimes by identifying issues before they escalate.

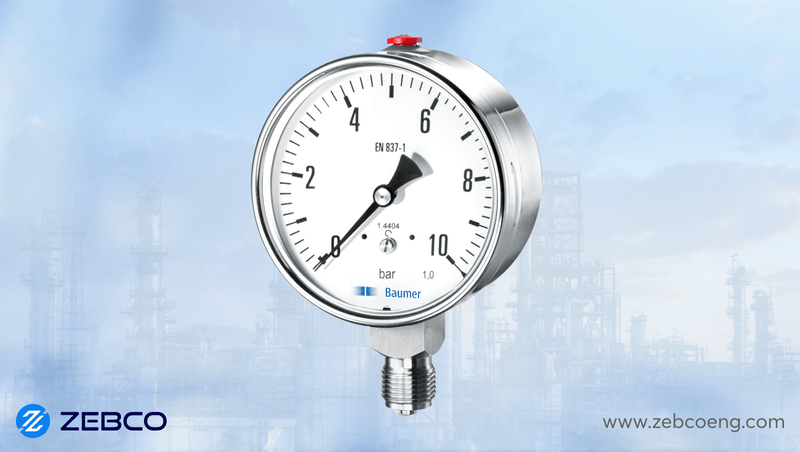

Baumer Pressure Gauges: Swiss Precision Engineering

Known for Swiss precision, Baumer manufactures pressure gauges designed for reliability and long-term stability. Their product range is ideal for environments where hygiene, compact design, and accuracy are crucial.

Popular Models:

Key Features:

- SS304/SS316 stainless steel construction

- High vibration resistance

- Wide dial sizes and pressure ranges

- Excellent for hygienic environments

Best For:

- Food & Beverage

- Pharmaceutical manufacturing

- Process automation

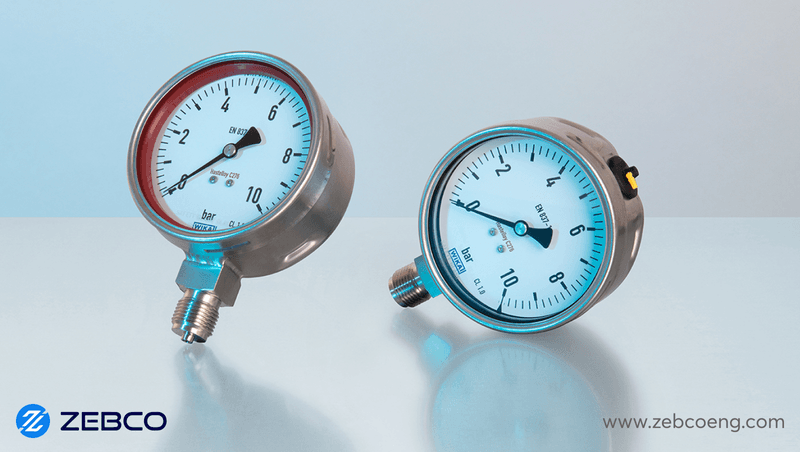

WIKA Pressure Gauges: German Engineering Excellence

WIKA stands out for its rugged, high-performance gauges built to handle the harshest environments. With advanced safety features and comprehensive certifications, WIKA is a trusted name in heavy industries.

Key Models:

Key Features:

- Fill options: glycerin, silicone, or dry

- Blow-out back for operator safety

- Custom dials and wetted parts

- Certifications: CE, EAC, ISO, ATEX

Ideal For:

- Hazardous and high-pressure environments

- Petrochemical and heavy industrial applications

How Zebco Helps You Choose the Right Pressure Gauge

Choosing the right pressure gauge isn’t one-size-fits-all. At Zebco Engineering, we offer personalized consultation based on:

- Media type: Gas, liquid, or corrosive

- Pressure range: Low to extremely high pressures

- Mounting style: Bottom, back, or panel

- Compliance needs: ISO, ATEX, CE certifications

Our experts help match your application needs with the ideal gauge. From food processing to oil rigs, we’ve supported diverse clients across India and beyond.

Why Buy from Zebco?

Zebco Engineering is your trusted partner for industrial instrumentation. As an authorized distributor of Baumer and WIKA, we ensure:

- Ready stock available in Ahmedabad

- Customizable dial sizes, thread types, and fill fluids

- Competitive pricing with fast global shipping

- Quick dispatch and responsive service

Which Gauge Should You Choose?

- Choose Baumer if you need hygienic, compact, and vibration-resistant gauges.

- Go with WIKA for extreme environments that demand durability and high safety compliance.

Not sure what’s best for your setup? Contact Zebco today for expert guidance and speedy delivery!

FAQ's

Baumer focuses on compact, hygienic applications with high vibration resistance. WIKA offers safety-enhanced gauges built for harsh environments.

It depends on the media type, pressure range, mounting style, and certification needs. Zebco provides expert consultation to help you decide.

Yes. Both brands comply with international standards like ISO, CE, RoHS, and ATEX.

Absolutely. Zebco offers customization for dial sizes, thread types, fill fluids, and wetted materials.

Yes. Models with SS316 construction and filled designs are ideal for such environments.