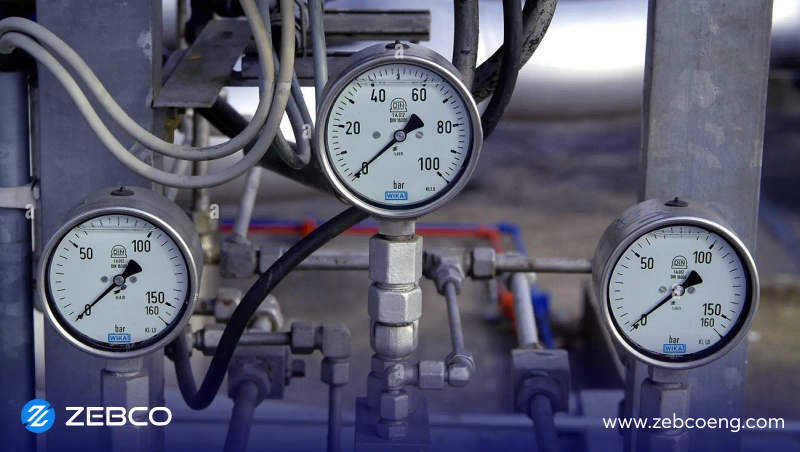

When precision and safety matter in pressure measurement, WIKA is the go-to name trusted across the globe. Two of their most widely used models-232.50 and 233.50- offer robust stainless-steel design for demanding environments. But which one is right for you?

In this blog, we’ll explain the technical differences, help you choose the correct model, explore international approvals, and highlight how Zebco Engineering LLP delivers superior value through technical expertise and genuine WIKA products.

1. WIKA 232.50 vs 233.50 – Technical Comparison

| Feature | WIKA 232.50 | WIKA 233.50 |

|---|---|---|

| Filling | Dry (Non-Filled) | Glycerine-Filled |

| Nominal Size | 100 / 160 mm | 100 / 160 mm |

| Wetted Parts | SS 316L | SS 316L |

| Case Material | Stainless Steel | Stainless Steel |

| Window | Laminated Safety Glass | Laminated Safety Glass |

| Ingress Protection | IP65 | IP65 |

| Application | Static pressure | Vibrations / Pulsation |

| Mounting Types | Bottom / Back / Panel | Bottom / Back / Panel |

2. Model Suitability – Which One is Right for You?

Choose WIKA 232.50 if:

- You’re working in vibration-free zones

- Media is clean and non-pulsating

- You need accurate readings at static conditions

Industries: Food & beverage, HVAC, water treatment, OEMs, general engineering

Choose WIKA 233.50 if:

- Process involves vibration, pressure spikes, or pulsation

- You need durable gauges for dynamic systems

Industries: Oil & gas, refineries, chemical, heavy machinery, marine, power plants

3. International Approvals & Certifications

WIKA’s 232.50 and 233.50 are globally approved and designed in accordance with stringent international safety standards.

| Certification/Standard | Description |

|---|---|

| EN 837-1 | European standard for pressure gauges |

| Nominal Size | Pressure Equipment Directive compliance |

| Wetted Parts | Explosion protection for Zone 1 / 2 environments |

| Case Material | Eurasian compliance certificate |

| Window | Registered for use in Canadian provinces |

| Ingress Protection | American standard for pressure gauges |

| Application | No hazardous materials used |

| Mounting Types | Manufactured under quality-certified systems |

Global Acceptance: These gauges are accepted in Europe, Middle East, North America, Russia, and Southeast Asia, making them a reliable choice for OEM exports, EPC contractors, and MNC procurement.

4. Preferred Industries That Use WIKA 232.50 & 233.50

- Oil & Gas Refineries – For rugged vibration-prone zones (233.50)

- Chemical & Petrochemical – Stainless steel wetted parts resist corrosion

- Power Plants – Steam systems with fluctuating pressures

- Pharma & Biotech – Clean media, high safety (with diaphragm seal option)

- Marine & Offshore – Salt air & vibration (233.50 with silicone fill)

- OEM Skid Builders – Compact, modular panels for export equipment

- Pumps & Compressors – Gauge dampening critical for durability

5. How Zebco Helps Technically with WIKA Gauges

As an authorized technical partner, Zebco Engineering LLP offers:

Technical Services:

- Application-specific gauge selection

- Media compatibility and material consulting

- Glycerine vs silicone fill options

- Pressure range customization (bar/psi/MPa)

- Dual-scale dial printing

- Diaphragm seal integration for harsh or clogging fluids

Customization Options:

- Rear or bottom mount versions

- Customized logo printing (for OEMs)

- Unique scales (like mH2O, kg/cm²)

- Panel mount with bezel rings

For OEMs & EPC Projects:

- Project documentation, data sheets & drawings

- Pre-dispatch calibration reports

- WIKA Germany-origin traceability

- Fast deliveries for urgent shutdowns

6. Why Zebco is the Preferred Partner for WIKA Products

| Reason | What Zebco Offers |

|---|---|

| Genuine Products | WIKA original gauges with serial number traceability |

| Technical Advice | Expert support for application engineering |

| Competitive Pricing | Dealer-level pricing even for small quantities |

| Fast Response | Same-day quote & dispatch (for in-stock items) |

| International Projects | Support for export documents, Form 10F, country of origin |

| After-Sales Support | Calibration, inspection, warranty replacement |

Estimated Price Range (India)

| Model | Dial Size | Price Range |

|---|---|---|

| WIKA 232.50 | 100 mm | ₹2,500 – ₹3,500 |

| WIKA 233.50 | 100 mm | ₹3,000 – ₹4,500 |

Prices vary based on quantity, range, mount type, and filling option.

Conclusion

Choosing between WIKA 232.50 and 233.50 is about matching the right product to the right environment. If your system has vibration or dynamic loads, the 233.50 with glycerine filling is the clear winner. For static and cleaner applications, the 232.50 offers reliability at a lower cost.

With Zebco Engineering LLP, you're not just buying a gauge—you're buying confidence, compliance, and customisation. Our team ensures every product is technically verified, quickly delivered, and backed by expert support. Let’s Talk!

Need help choosing the right pressure gauge for your application?

FAQs – Frequently Asked Questions

Yes, it is ideal for compressors, pumps, and mobile machinery due to glycerine filling.

Yes. We can supply ATEX-approved versions of both 232.50 and 233.50 on request.

Common models (0–10 bar, 1/2” NPT) are usually available within 2–4 working days. Bulk or special-range models: 1–2 weeks.

Yes. We provide WIKA calibration certificates and NABL-accredited third-party calibration when required.

Absolutely. We assist with GST exemptions, Form 10F, Country of Origin Certificates, and packing with international markings.