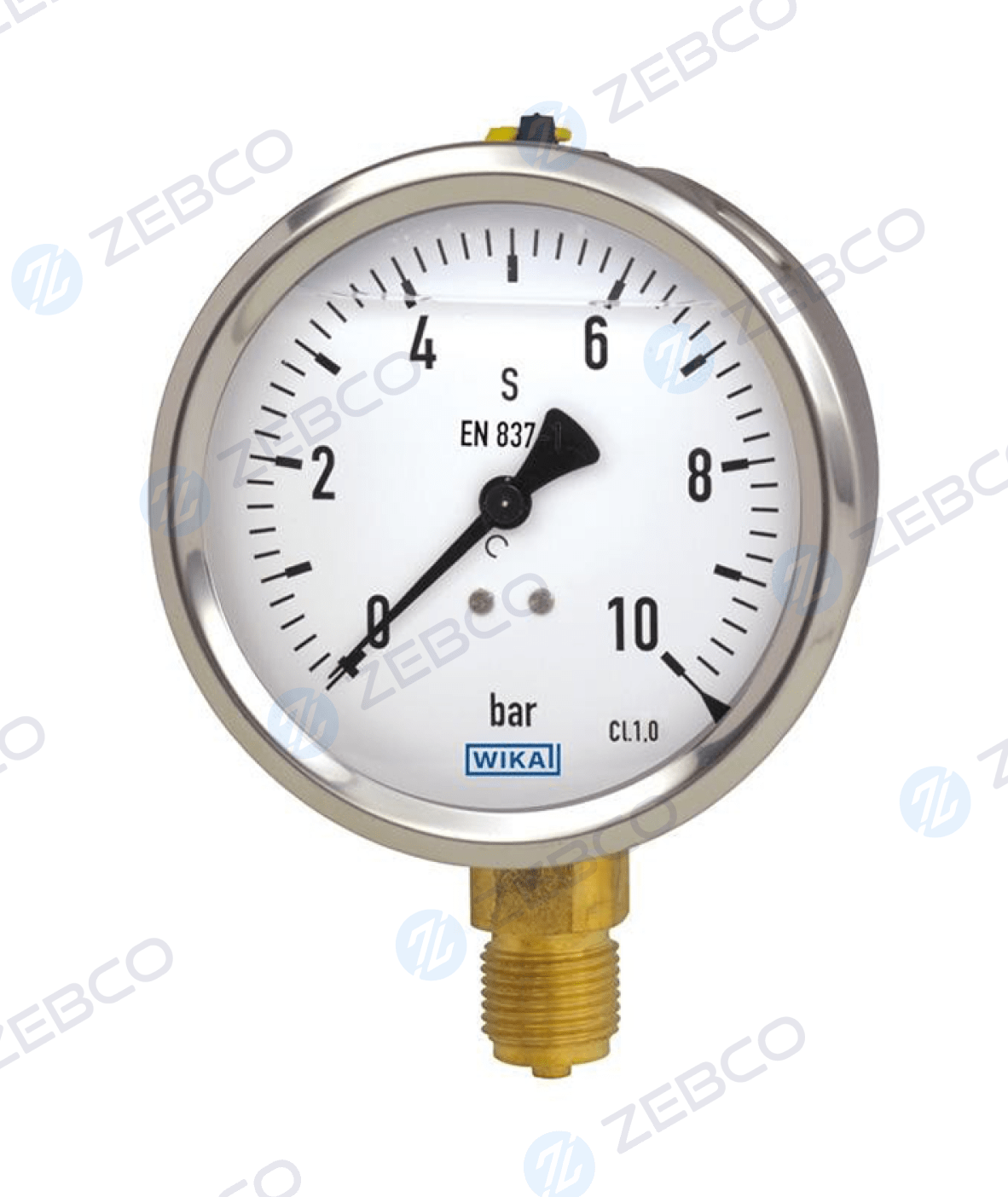

Wika Filled Pressure Gauge

(Model: 213.53 )

At Zebco Engineering, we supply in India and export Wika Liquid Filled Pressure Gauges (Model: 213.53), designed for reliable performance and vibration resistance in industrial environments.

- Very good vibration and shock resistance

- Especially robust design

- Type approval for the shipbuilding industry

- Scale ranges to 0 ... 1,000 bar or 0 ... 15,000 psi

Application

- For measuring locations with high dynamic pressure loads and vibrations

- For gaseous and liquid media that are not highly viscous or crystallising and will not attack copper alloy parts

- Hydraulics

- Compressors, shipbuilding

Descriptions ( Liquid Filled Gauge - Model: 213.53 )

The liquid-filled model 213.53 mechanical Bourdon tube pressure gauge is constructed with a case from stainless steel and wetted parts from copper alloy.

WIKA manufactures and qualifies the pressure gauge in accordance with the standards EN 837-1 and ASME B40.100. As a safety function, this instrument has a blow-out device. In the event of a failure, overpressure can escape there.

Due to the case filling, the pressure element and movement are efficiently damped. Therefore, these instruments are particularly suited to measuring locations with high dynamic loads, such as fast load cycles or vibrations.

The cases of the model 213.53 are available in nominal sizes of 50 [2], 63 [2 ½] and 100 [4] and fulfil IP65 ingress protection. With an accuracy of up to class 1.0, this pressure gauge is suitable for a wide range of applications in industry. For mounting in control panels, the pressure gauges with a back mount process connection can be fitted with a mounting flange or with a triangular profile ring and mounting bracket.

Specifications

| Standard |

| |

| Further version |

| |

| Nominal size (NS) |

| |

| Connection location |

| |

| Window |

| |

| Case | - | |

| Design |

| |

| Material |

| |

| Ring |

| |

| Mounting |

| |

| Case filling |

| |

| Movement |

| |

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!