Zebco Industrial Strainers – Reliable Manufacturers & Exporters

Zebco manufactures high-quality industrial strainers, including Y-type, for effective filtration across various applications. Our strainers protect equipment by filtering contaminants, supporting system longevity, and ensuring operational efficiency across industrial sectors.

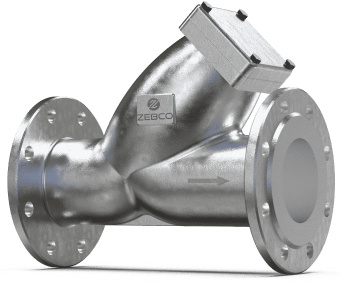

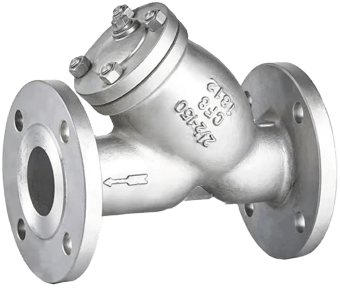

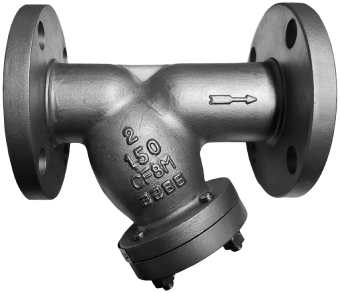

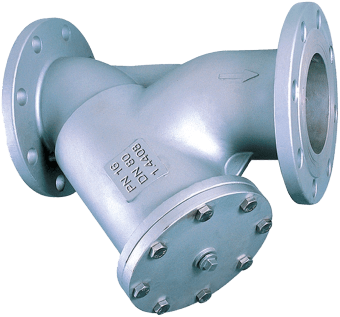

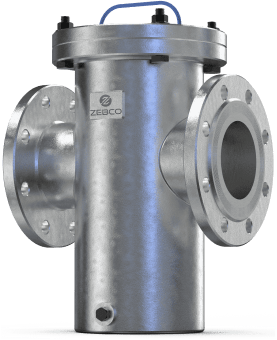

Y-type Strainer

Discover filtering excellence with Zebco's Precision Strainer. Engineered for optimal performance in diverse industrial applications, our strainer ensures efficient filtration and reliable operation. Versatile and compliant with industry standards, it's the trusted choice for oil and gas, petrochemicals, and water treatment. Elevate your fluid control systems with Zebco's Precision Strainer.

| Design | : | B16.34 |

| Connection type | : | 1.END FLANGE(RF/RTJ):ASME B16.5 (2” to 24”) 2.BUTT WELD(BW):ASME B16.25 |

| Face to Face | : | ASME B16.10; |

| Test | : | API 598; |

| Product range | : | Size: NPS 2″~24″(DN50~DN600) Pressure Rating: ASME CLASS 150LB~2500LB(PN16~PN420) |

Material of body

| Carbon Steel | WCB, WCC |

| Low Temperature Steel | LCB, LCC |

| Stainless Steel | CF8, CF8M, CF3, CF3M, CF8C, CF10, CN7M, CG8M, CG3M |

| Alloy Steel | WC6, WC9, C5, C12, C12A |

Features and Benefits

- Zebco Valve’s Y-Shaped Design allows for efficient flow of fluids and provides a larger filtration area compared to other strainer types.

- Removable Strainer Element: The purpose of a Y strainer is to effectively remove unwanted particles from steam, gas, or liquid by utilizing a straining element typically made of wire mesh. This mechanical process helps safeguard various components such as pumps and steam traps. Some Y strainers are equipped with blow-off valves to facilitate easier cleaning.

- Inline Installation: Y-type strainers are installed directly in the pipeline, providing an inline filtration solution. They can be mounted horizontally or vertically, depending on the flow direction and installation requirements.

- Blowdown/Flush Connection: Y-type strainers often feature a blowdown or flush connection. This allows for periodic cleaning or removal of accumulated debris from the strainer element without having to disassemble the entire strainer.

- Flow Efficiency: The Y-shaped design of the strainer minimizes pressure drop and turbulence, ensuring a smooth and uninterrupted flow of fluid through the system. This helps to optimize system performance and reduce energy consumption.

- Versatility: One of the significant advantages of Y strainers is their versatility. They can be installed in either a vertical or horizontal position, depending on the user's preference. Additionally, Y strainers offer cost-effectiveness, as their size can be optimized to save on materials and expenses. The choice of material for Y strainers depends on the specific industry and application requirements. Moreover, Y strainers are available with various end connections, including socket and flanged options, ensuring compatibility with different piping systems.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!