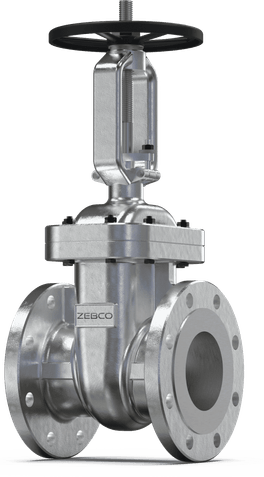

Top-Quality Gate Valves – Manufacturer & Supplier in Saudi Arabia

At Zebco Engineering, we provide high-quality gate valves for industries in Saudi Arabia. Our valves are available in materials like stainless steel, carbon steel, brass, cast iron, and more, with custom specifications to fit your needs. With stock always ready, we ensure your operations run smoothly and efficiently.

Top Gate Valve Manufacturer | Trusted by Saudi Arabia

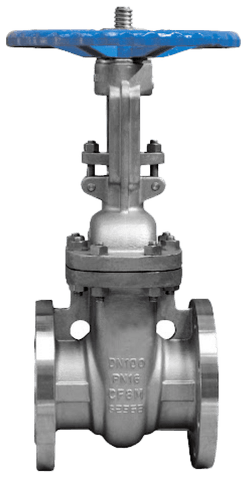

Zebco Engineering offers API-approved gate valves in Saudi Arabia, crafted from high-quality materials like carbon steel, stainless steel, & alloy steel. Available in classes like 150, 300 & more, ensuring reliable performance for Saudi Arabia’s industries.

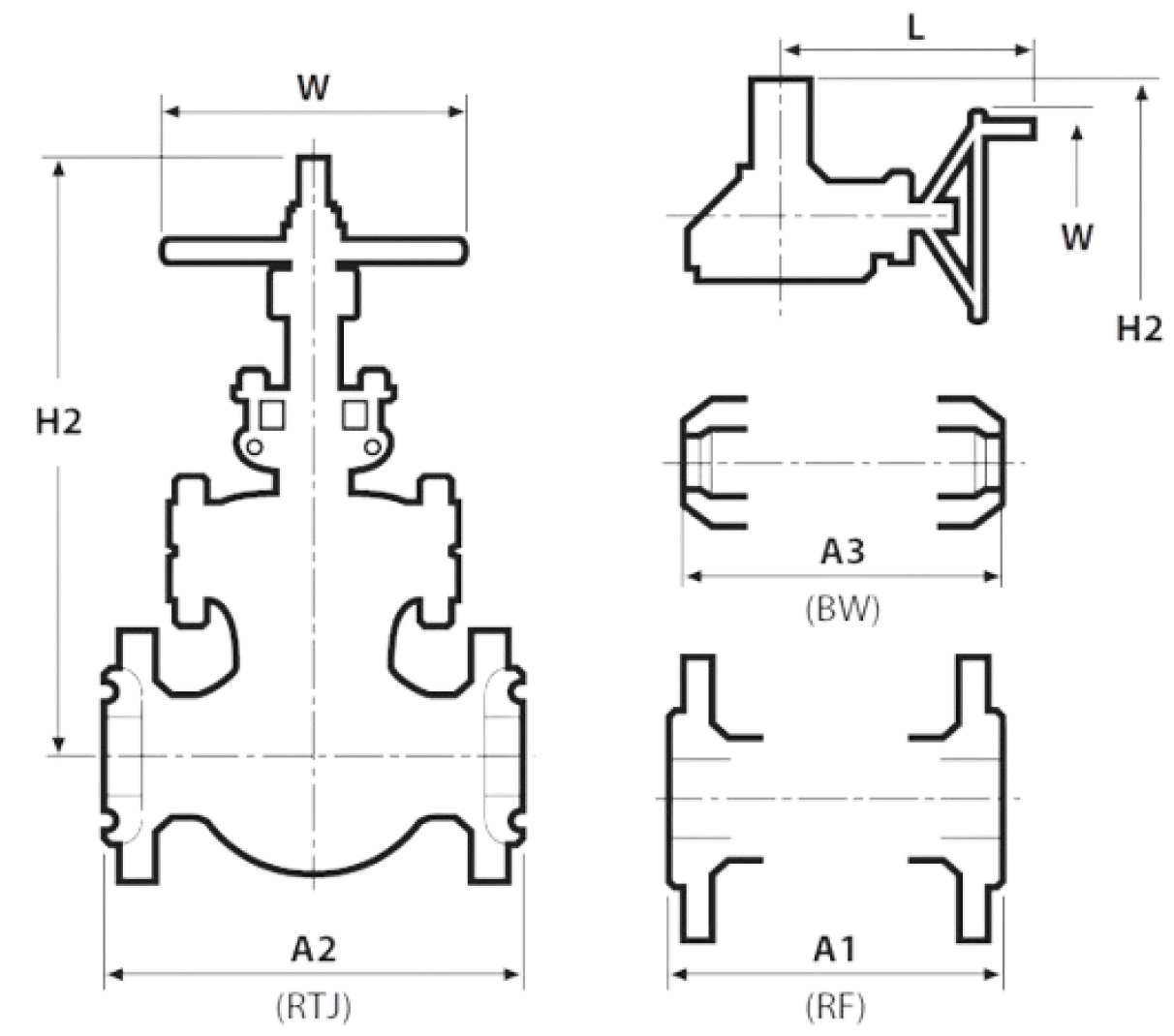

| Design | : | API 600 / ASME B16.34 / BS 1414 |

| Face to Face | : | ASME B16.10, DIN3202, EN 558-1 |

| End to End | : | Flanged End / SW/BW Type / RTJ |

| Pressure - Temp. Rating | : | ASME B 16.34 |

| Materials (Body | Bonnet) | : | WCB, WC6, WC9, WCC, CF8, CF3, CF3M, CF8M, 4A, 5A |

| Flange End | : | ASME B 16.5 |

| Test Standard | : | API 598/BS EN 12266-1 |

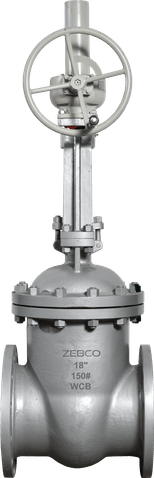

| Operation | : | Manual | Gear | Electrical Actuated |

| Size | : | 1/2” up to 88“ (DN 50 up to DN 2200) |

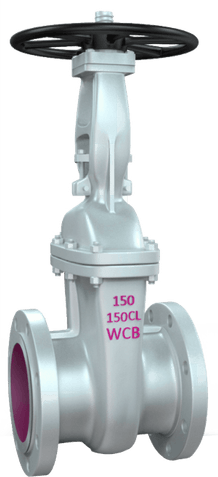

| Class | : | 150# - 2500# |

Gate Valves in Saudi Arabia: Key Functions and Industrial Uses

TRUSTED MANUFACTURER, EXPORTER & SUPPLIER OF HIGH QUALITY GATE VALVE IN SAUDI ARABIA

In Saudi Arabia, reliable gate valves are essential for industrial operations. Zebco Valves offers superior valve solutions with certifications like ISO 9001 and API 600 to ensure peak performance across various sectors. Our range includes ASME Class 150, 300, and 600 bolted bonnet cast steel valves, available with metal-to-metal seating, flanged or butt weld ends, and materials like carbon steel, stainless steel, and alloy steel.

Whether it's high-pressure systems or extreme environments, Zebco Valves delivers valves designed for durability and efficiency. We serve Saudi industries such as oil and gas, petrochemicals, and cryogenics, providing reliable solutions tailored to their unique needs.

With Zebco, your industrial processes are in safe hands. Our valves are built for reliability, offering peace of mind with every operation.

Benefits of Gate Valves for Saudi Arabia Industries

Zebco Engineering's Bolted Bonnet Flexible Wedge Gate Valves are engineered to meet the rigorous demands of high-pressure steam systems, catalytic reformers, hydrocrackers, and other challenging applications in Saudi Arabia.

- Precision Engineering: Connection flanges between the body and bonnet are meticulously designed in accordance with ASME standards, ensuring optimal performance.

- Enhanced Durability: A robust, leak-proof bolted body-bonnet joint provides superior tightness and durability, achieved through higher bolting torque.

- Advanced Design for Larger Sizes: For sizes DN650 (NPS 26”) and above, wedge and body guides are surface-hardened to increase strength and longevity.

- Improved Stability: The extended and widened body ram guide mating surface offers additional stability, enhancing valve performance.

- Reduced Wear: Wedge guiding minimizes seat rubbing and scuffing, contributing to a longer service life and reduced maintenance needs.

- High-Strength Materials: The body is constructed from high-strength forgings or optional cast steel, ensuring exceptional performance under demanding conditions.

- Erosion-Resistant Seating: Hard-faced seating surfaces are resistant to erosion, extending valve life and reliability.

- Optional Seal Weld: The valve is available with a provision for a seal weld, providing extra sealing security when required.

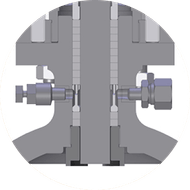

- Low-Emission Packing: API 622 packing is used for low-emission applications, ensuring environmental compliance.

Additionally, Zebco's wedge gate valves can be customized with a bypass valve and bellow seal based on customer specifications. For custom sizing, please request a quote.

Choose Zebco Valves in Saudi Arabia for precision-engineered solutions designed to withstand tough industrial conditions.

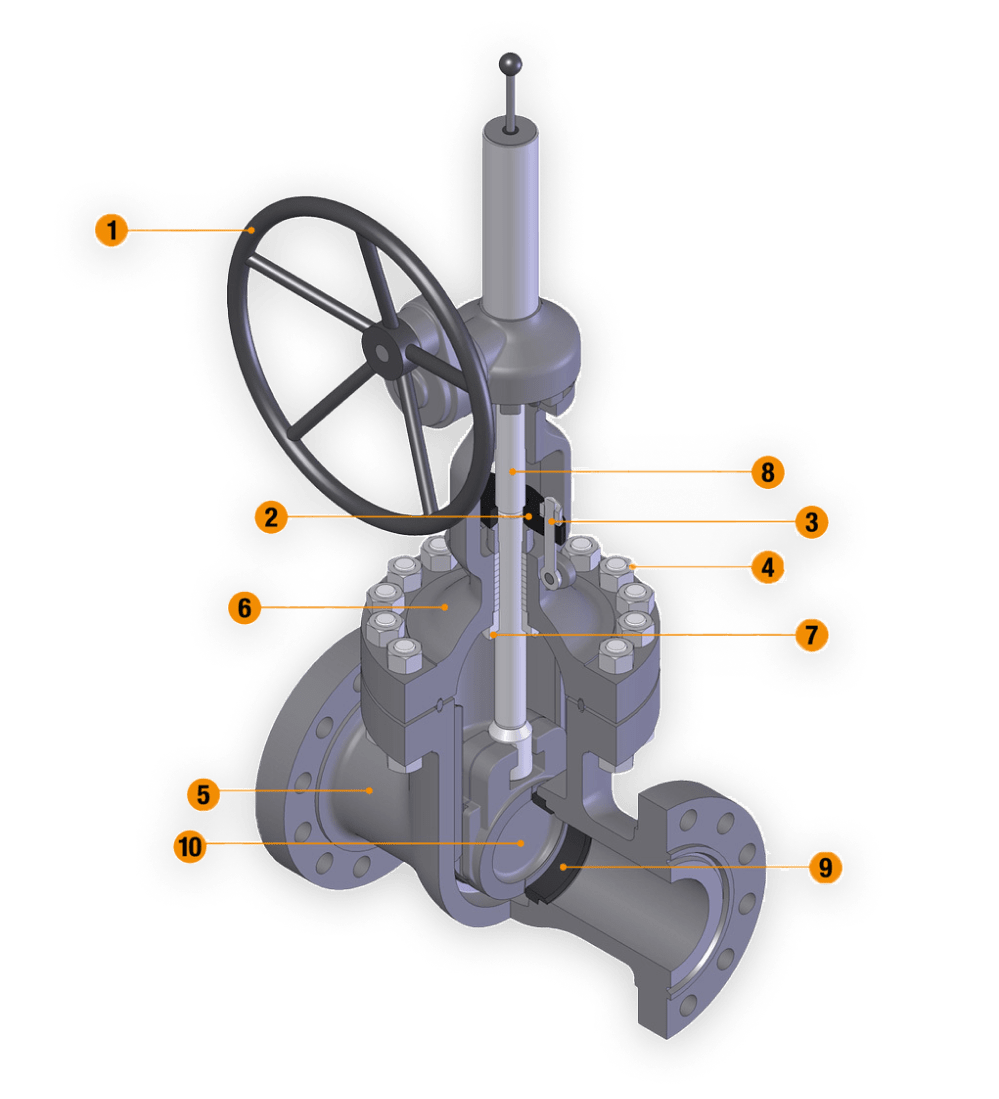

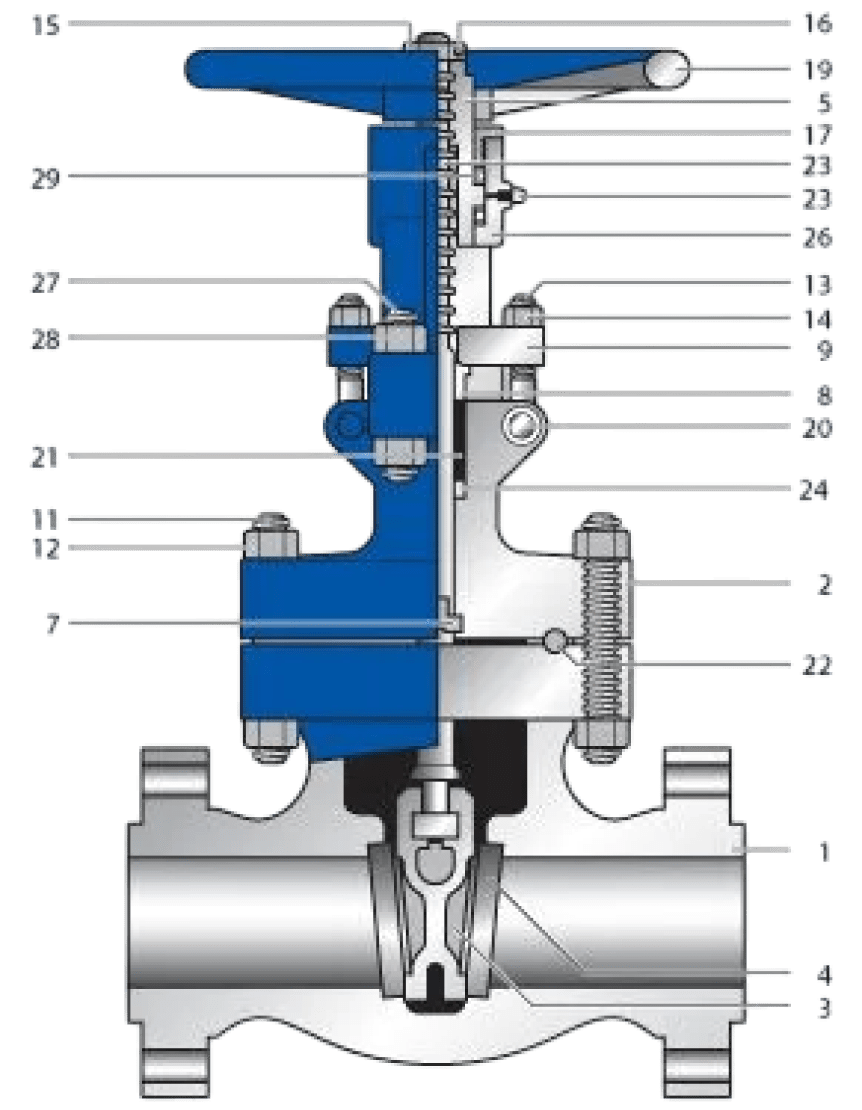

An In-Depth Look at Gate Valve Construction

Gate Valves consist of three main parts: body, Bonnet, and trim. The body is generally connected to other equipment by means of flanged, screwed or welded connections. The Bonnet, which containing the moving parts, is attached to the body, usually with bolts, to permit maintenance. The Valve trim consists of the stem, the gate, the disc or wedge and the seat rings.

CAST OR FORGED STEEL BODY, OUTSIDE SCREW AND YOKE, RISING STEM, NON-RISING OPERATOR, RENEWABLE SEATS, REMOVABLE YOKE SLEEVE, BACKSEAT FOR REPACKING UNDER PRESSURE.

Welded - in seat ring

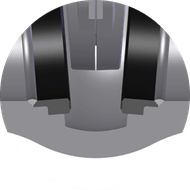

FLEX WEDGE

LANTERN RING

| 1. OPERATOR | The spoked handwheel is fabricated from steel pipe. The hub is coupled to the yoke sleeve by means of a key. Larger valves are equipped with a bevel or spur gear gearbox unit. |

|---|---|

| 2. GLAND AND FLANGE | They are in forged steel and are normally supplied in two pieces, self aligning design to permit the gland to descend parallel to the stem even if the eyebolts are unevenly tightened. |

| 3. GLAND BOLTS AND NUTS | The forged steel gland bolts are of the eyebolt type which can be swung outward for ease of gland repacking. They are fixed to the bonnet by hinge pins. |

| 4. BONNET BOLTING | Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard. The body to bonnet connection is designed according to ASME VIII DIV 1 standard. |

| 5. BODY | The body is in carbon or stainless steel and is available in many other CRA. It is carefully designed for total reliability and simple maintenance. The basic dimension, i.e. wall thickness, face to face and flanges comply with the relevant API and ASME standards. The body-to-bonnet flange is circular, except in the Class 150 where it is oval. The body-to-bonnet joint are flat face on Class 150 valves, male-and-female on Class 300 and ring joint on Class 600 and above. |

| 6. BONNET | As the body, the bonnet is in carbon or stainless steel and is available in many other CRA. It is machined to accept yoke sleeve and incorporates a stuffing box sized in accordance with the API standard. Lifting lugs can be provided integrally cast on the bonnet surface. |

| 7. BONNET BUSHING | The bonnet bushing or backseat is part of the valve trim. Its design allows valve repacking without valve’s bleeding or draining. Hardfacing can be provided on stem seating surface. |

| 8. STEM | The stem is part of the trim and is available in a wide range of material in accordance to API 600 or customer’s requirements. The stem is provided with a T-shaped head. A ground backseat is provided to ensure a perfectly tight seal to the stuffing box when the valve is fully open. The stem is highly finished in order to minimize friction and prevent damage to the packing. The thread is trapezoidal ACME type. All the stem sizes comply with the API 600 standard. |

| 9. SEAT RINGS | Welded-in seat rings are supplied as a standard. The rings are part of the trim of the valve. They can be externally threaded and internally notched for easy installation and dismantling. Special attention is given to the seating surfaces which are ground and lapped for a tight seal. |

| 10. WEDGE | The wedge is the main part of the trim. It is forged or cast in carbon or stainless steel and also available in CRA material. It is normally supplied as the solid wedge type. It is connected to the stem by means of a T-shaped joint. The guides on each side of the wedge are machined. Special care is given to the seating surfaces which are ground and lapped, integral or hardfaced. A cladding or lining can be applied to the wedge to improve its resistance against erosive and corrosive environments. For improved seating and unseating easiness, it can be machined with the flexible option. |

CARBON & STAINLESS STEEL WEDGE GATE VALVE CLASS 150 - 1500

| No. | Name of Part | ASTM Specification | ||||||

|---|---|---|---|---|---|---|---|---|

| CARBON STEEL | HIGH-TEMPERATURE SERVICE | LOW TEMPERATURE SERVICE | STAINLESS STEEL | |||||

| 1 | BODY | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 2 | BONNET | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 3 | DISC | A216-CR13/SS316 | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 4 | BODY SEAT RING | SS316 + HARD FACE | A182-F11 | A182-F22 | A182-F5A | A182-F304 | F316 | F347 |

| 5 | STEM | CR13/A182-SS316 | A182-F6A | A182-F6A | A182-F6A | A182-F304 | F316 | F347 |

| 6 | BONNET BUSH | A276-410/A182-SS316 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 7 | PACKING GLAND | A276-410/A182-SS316 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 8 | GLAND FLANGE | A105 | A105 | A105 | A105 | A350-LF2 | CF8M | CF8C |

| 9 | YOKE SLEEVE | A439-D2C | A439-D2C | A439-D2C | A439-D2C | B147-B8 | F316 | F347 |

| 10 | BONNET BOLT | A193-B7M | A193-B16 | A193-B16 | A193-B16 | A320-L7M | A193-B8 | A193-B8 |

| 11 | BONNET NUT | A194-2HM | A194-4 | A194-4 | A194-4 | A194-7M | A194-8 | A194-8 |

| 12 | GLAND BOLT | A193-B7M | A193-B7 | A193-B7 | A193-B7 | A320-L7M | A193-B8 | A193-B8 |

| 13 | GLAND NUT | A194-2HM | A194-2H | A194-2H | A194-4 | A194-7M | A194-8 | A194-8 |

| 14 | HANDLE NUT | STEEL | ||||||

| 15 | SET SCREW | STEEL | ||||||

| 16 | SLEEVE GLAND | STEEL | ||||||

| 17 | HANDWHEEL | A395 | ||||||

| 18 | HINGE PIN | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 19 | PACKING | COMMERCIAL | ||||||

| 20 | GASKET | SPIRAL WOUND + GRAPHITE / RING JOINT | ||||||

| 21 | GREASE NIPPLE | STEEL | BRONZE | BRONZE | ||||

| 22 | LANTERN | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 23 | YOKE | A216-WCB | A216-WC6 | A216-WC9 | A216-C5 | A352-LCC/LC1/LC2/LC3 | CF8M | CF8C |

| 24 | YOKE BOLT | A193-B7M | A193-B16 | A193-B16 | A193-B16 | A320-L7 | A193-B8 | A193-B8 |

| 25 | YOKE NUT | A194-2HM | A194-4 | A194-4 | A194-4 | A194-4 | A194-8 | A194-8 |

| 26 | BEARING | STEEL | ||||||

Zebco Engineering: No. 1 Valve Manufacturer & Supplier for Saudi Arabia’s Industries

Zebco Engineering is a leading مورد (supplier) and صانع (manufacturer) of high-quality industrial valves in Saudi Arabia. We specialize in customizing valve solutions to meet the specific needs of industries across the Kingdom.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!