Top Globe Valve Supplier: Manufacturing & Stocking in Saudi Arabia

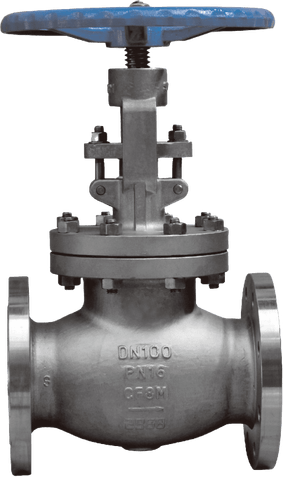

Zebco Engineering is a leading supplier & manufacturer of premium globe valves in Saudi Arabia.We provide valves crafted from materials like stainless steel, carbon steel, brass & others available in pressure classes 150 to 900, ideal for Saudi Arabia Industries.

High-Quality Globe Valve Supplier in Saudi Arabia | Zebco

Zebco is a trusted manufacturer, supplier & stockist of API-approved globe valves in Saudi Arabia. We provide reliable and high-performance flow control solutions, designed to enhance the efficiency and reliability of your operations.

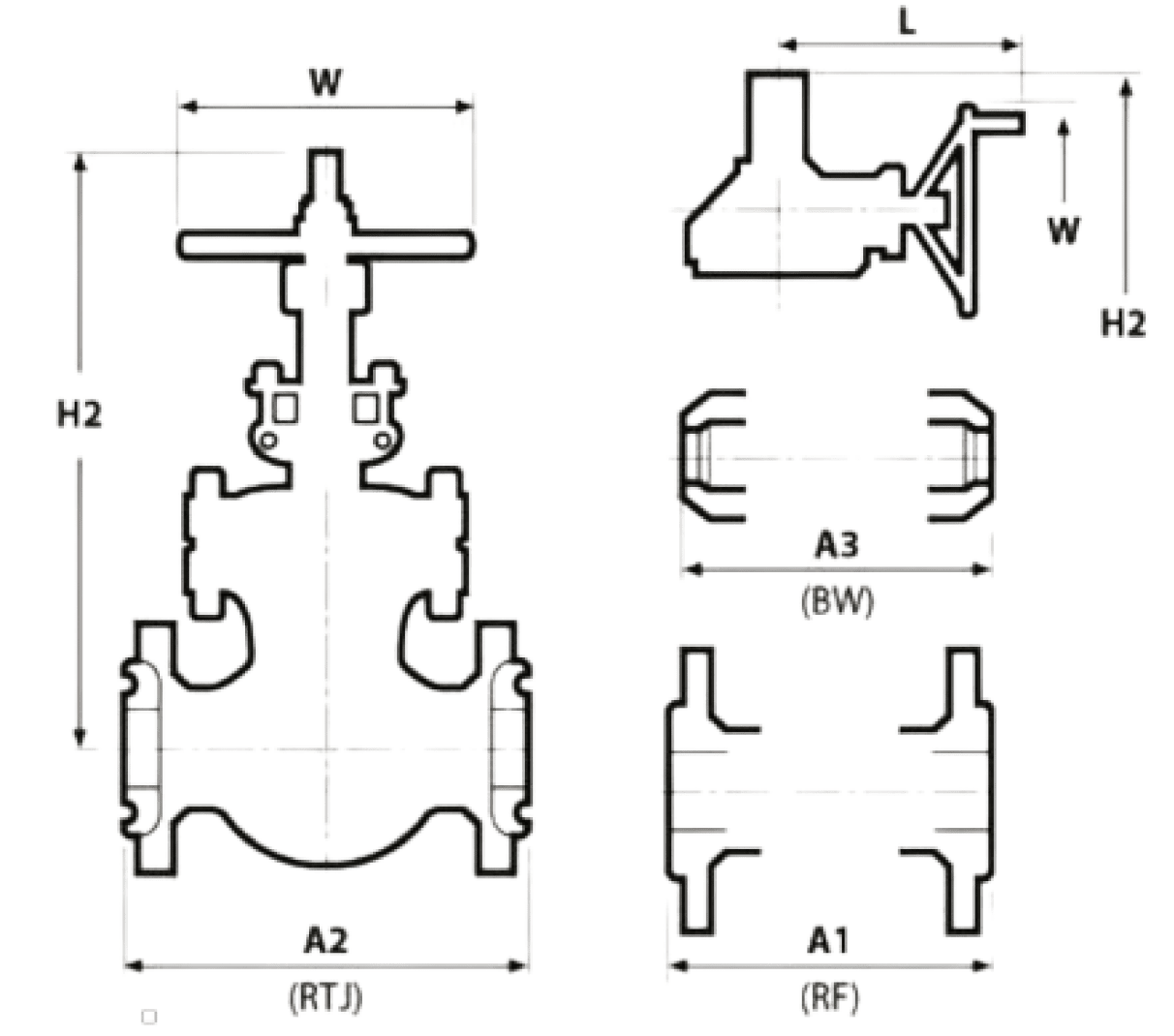

| Design | : | ASME B16.34 / BS 1873 |

| Face to Face | : | ASME B16.10 / DIN IS |

| End to End | : | BW Type / Flanged End / RTJ |

| Pressure - Temp. Rating | : | ASTM B 16.34 |

| Materials (Body | Bonnet) | : | WCB / CF8 / CF8M/ CS / SS / Alloys / Monel / Hastalloys Steel / Bronze MOC |

| Flange End | : | ASME B 16.5 |

| Test Standard | : | API 598 / BS 6755 |

| Operation | : | Manual | Gear | Electrical Actuated |

| Size | : | 1/2” up to 24“ (15NB - 500NB) |

| Class | : | 150# - 2500# |

What is a Globe Valve? A Guide for Saudi Arabia’s Industries

Top TRUSTED MANUFACTURER, EXPORTER, AND SUPPLIER OF API APPROVED GLOBE VALVE IN SAUDI ARABIA

If you're looking for globe valves you can count on, Zebco Engineering is here to provide you with reliable solutions in Saudi Arabia. Our valves are crafted to meet the highest industry standards, including API 623, ensuring they perform seamlessly even under the toughest conditions. With our ISO 9001 certification, we’re committed to delivering products that stand the test of time.

We understand the challenges faced by industries like oil and gas, petrochemicals, cryogenics, and hydrogen processing. That's why our valves are designed to withstand high pressures and extreme temperatures. With options available in ASME Class 150, 300, and 600, you’ll find the right fit for your needs. Our range of materials, including Carbon Steel, Stainless Steel, Inconel, Hastelloy, and more, ensures that we have the perfect solution for your specific application.

Whether you’re managing a large-scale project or need precise control, our valves are built with you in mind. When you choose Zebco, you're choosing more than just a valve—you're choosing peace of mind, knowing that our products are designed to support your operations. We're here to make your work easier and more efficient, every step of the way. Let Zebco guide you to the right solution, because for us, quality is not just a promise, it’s our way of doing business.

Why Globe Valves: Key Advantages for Saudi Arabia Industries

The globe valve is a simple yet effective valve design widely used in various industrial applications in Saudi Arabia. It features a single sealing surface on both the valve body and valve flap, making it cost-effective and easier to manufacture, while reducing maintenance needs.

The valve’s sealing surfaces experience minimal wear and abrasion, ensuring long-lasting performance. Unlike other valve types, there is no significant relative movement between the valve flap and body sealing surface (except for conical sealing surfaces), ensuring smooth operation and better sealing over time.

- Precise Flow Control: Globe valves are ideal for controlling fluid flow with precision. They can be easily adjusted to achieve a range of flow rates, making them suitable for diverse industrial applications in Saudi Arabia.

- High-Pressure Rating:Globe valves are well-suited for high-pressure applications, providing a robust solution for critical systems in industries such as oil, gas, and petrochemicals, commonly found in Saudi Arabia.

- Reliable Shutoff: These valves are designed to deliver tight shutoff, effectively preventing fluid flow in both directions when needed, ensuring system safety.

- Versatility:Globe valves are capable of handling various types of fluids, including gases, liquids, and slurries. This makes them valuable for industries such as petrochemical, manufacturing, refining, and water treatment across Saudi Arabia.

- Long Lifespan: With proper maintenance, globe valves offer long-term durability and are less prone to leakage, which helps protect equipment and prevents costly downtime.

Choose Zebco Engineering’s globe valves for dependable, high-performance solutions that cater to the demanding industrial needs of Saudi Arabia.

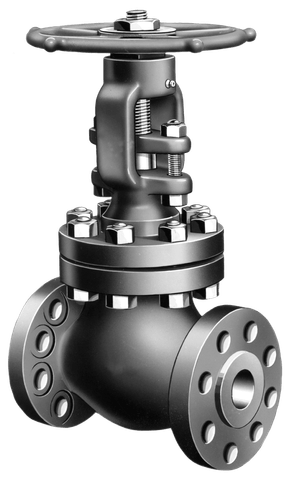

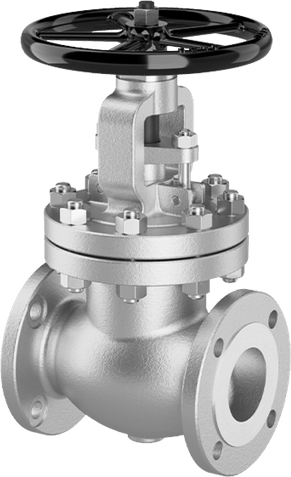

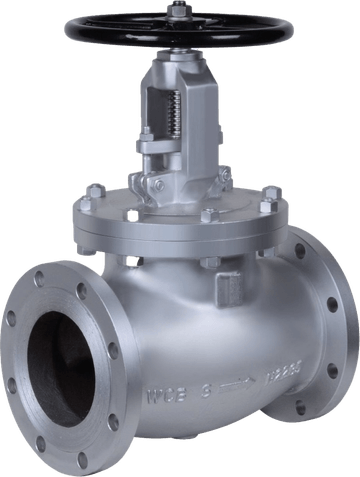

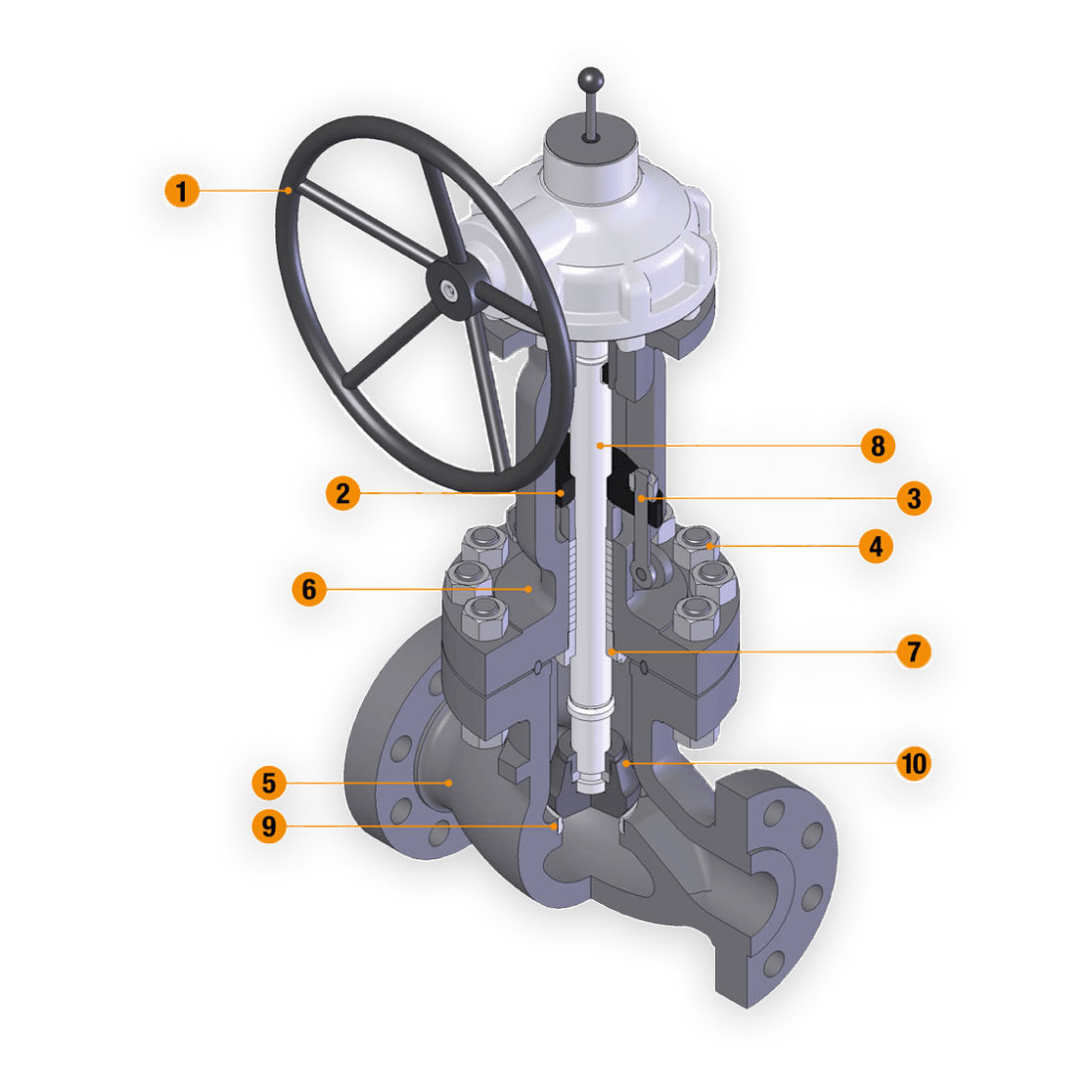

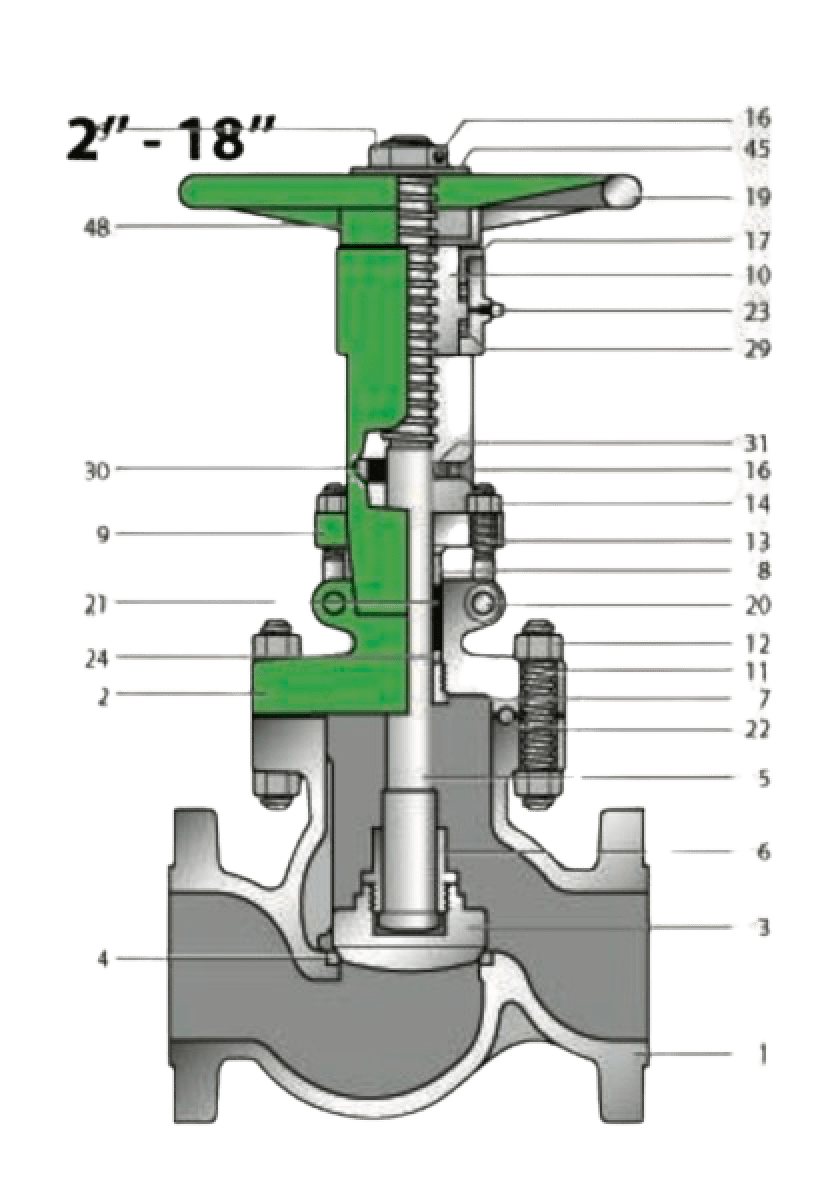

Exploring the Design of Zebco Globe Valves

Globe Valves consists of three main parts: body, Bonnet, and trim. The body is generally connected to other equipment by means of flanged, screwed or welded connections. The Bonnet, which containing the moving parts, is attached to the body, usually with bolts, to permit maintenance. The Valve trim consists of the stem, the disc and the seat rings.

CAST STEEL BODY, OUTSIDE SCREW AND YOKE, RISING STEM, NON-RISING OPERATOR, RENEWABLE SEATS, REMOVABLE YOKE SLEEVE, BACKSEAT FOR REPACKING UNDER PRESSURE.

REGULATING DISC

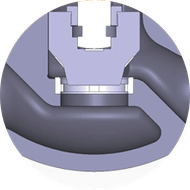

STOP - CHECK DISC

LANTERN RING

| 1. OPERATOR | The spoked handwheel is fabricated from steel pipe. The hub has a square hole for coupling with the stem, and for large sizes the hube is coupled with the yoke sleeve by means of a tongue. |

|---|---|

| 2. GLAND AND FLANGE | They are in forged steel and are supplied in two pieces, self aligning design in order to allow the gland to slide parallel to the stem even if the eyebolts are unevenly tightened. |

| 3. GLAND BOLTS AND NUTS | The forged steel gland bolts are of the eyebolt type which can be swung outward for ease of gland repacking. They are fixed to the bonnet by hinge pins. |

| 4. BONNET BOLTING | Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard. The body to bonnet connection is designed according to ASME VIII DIV 1 standard. |

| 5. BODY | The body is in carbon or stainless steel and is also available in many other CRA. It is carefully designed for total reliability and simple maintenance. The basic dimension, i.e. wall thickness, face to face and flanges comply with the relevant BS and ASME standards. The body-to-bonnet flange is circular. The body-to-bonnet joint are male-and-female on Class 150 and 300 and ring joint on Class 600 and above. The body is basically supplied with renewable seats. Bosses are provided for draining connections. |

| 6. BONNET | As the body, the bonnet is in carbon or stainless steel and is available in many other CRA. It is machined to accept yoke sleeve and incorporates a stuffing box sized in accordance with the BS standard. Lifting lugs can be provided integrally cast on the bonnet surface. |

| 7. BONNET BUSHING | The bonnet bushing or backseat is part of the valve trim. Its design allows valve repacking without valve’s bleeding or draining. Hardfacing can be provided on stem seating surface. |

| 8. STEM | The stem is part of the trim and is available in a wide range of material in accordance to BS1873, API 600 or customer’s requirements. The stem is provided with a ground backseat in order to ensure a perfectly tight seal to the stuffing box when the valve is fully open. The stem is highly finished in order to minimize friction and prevent damage to the packing. The thread is trapezoidal ACME type. All the stem sizes comply with the BS 1873 standard. |

| 9. SEAT RINGS | Threaded and seal-welded seat ring is supplied as a standard. The seats are part of the trim of the valve. They can be simply threaded for easy installation and dismantling. Special attention is given to the seating surface which is ground and lapped for a tight seal. |

| 10. DISC | The disc is the main part of the trim. It is connected to the stem by means of a swiveling half rings coupling and is guided in the body from 4” and above. The standard sealing profile is a spherical surface seating against a conical seat. If required a conical to conical seating can be supplied, and for flow throttling operations a regulating disc is adopted, shaped in order to give a linear opening. The stop check execution shows an externally guided disc, disconnected from the stem. A cladding or lining can be applied to larger discs to improve its resistance against erosive and corrosive environments. |

GLOBE VALVE

| No. | Name of Part | ASTM Specification | ||||||

|---|---|---|---|---|---|---|---|---|

| CARBON STEEL | HIGH-TEMPERATURE SERVICE | LOW TEMPERATURE SERVICE | STAINLESS STEEL | |||||

| 1 | BODY | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 2 | BONNET | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3/LCC | CF8M | CF8C |

| 3 | DISC | A105 + CR13 | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3/LCC | CF8M | CF8C |

| 4 | BODY SEAT RING | A105 + HARD FACE | A182-F11 | A182-F22 | A182-F5A | A182-F304 | F316 | F347 |

| 5 | STEM | A276-410 | A182-F6A | A182-F60 | A182-F6Q | A182-F304 | F316 | F347 |

| 6 | DISC GLAND | A217-CA15 | A217-CA15 | A217-CA15 | A217-CA15 | A182-F304 | F316 | F347 |

| 7 | BONNET BUSH | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 8 | PACKING GLAND | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 9 | GLAND FLANGE | A105 | A105 | A105 | A105 | A360-LF2 | CF8M | CF8C |

| 10 | YOKE SLEEVE | A439-D2C | A439-D2C | A439-D2C | A439-D2C | B147-B8 | F316 | F347 |

| 11 | BONNET BOLT | A193-B7M | A193-B16 | A193-B16 | A193-B16 | A320-L7M | A193-B8 | A193-B8 |

| 12 | BONNET NUT | A194-2HM | A194-4 | A194-4 | A194-4 | A194-7M | A194-8 | A194-8 |

| 13 | GLAND BOLT | A193-B7M | A193-B7 | A193-B7 | A193-B7 | A320-L7M | A193-B8 | A193-B8 |

| 14 | HANDLE NUT | STEEL | ||||||

| 15 | SET SCREW | STEEL | ||||||

| 16 | SLEEVE GLAND | STEEL | ||||||

| 17 | HANDWHEEL | A395 | ||||||

| 18 | GLAND NUT | A194-2HM | A194-2H | A194-2H | A194-2H | A194-4 | A194-8 | A194-8 |

| 19 | HINGE PIN | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 20 | PACKING | GRAPHITE | ||||||

| 21 | GASKET | SPIRAL WOUND + GRAPHITE / RING JOINT | ||||||

| 22 | GREASE NIPPLE | STEEL | BRONZE | BRONZE | ||||

| 23 | LANTERN | A276-410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 24 | BEARING | COMMERCIAL | ||||||

| 25 | STOPPER | A283-D | ||||||

| 26 | KEY | STEEL | ||||||

| 27 | WASHER | STEEL | ||||||

| 28 | IMPACT | A216-WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

Zebco Engineering: No. 1 Valve Manufacturer & Supplier for Saudi Arabia’s Industries

Zebco Engineering is a leading مورد (supplier) and صانع (manufacturer) of high-quality industrial valves in Saudi Arabia. We specialize in customizing valve solutions to meet the specific needs of industries across the Kingdom.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!